Troubleshooting

Guide

35|

Page

DESCALING

THE

UNIT

Hard

water

is

a

severe

problem

for

the

copper

coils

inside

heat

exchangers.

Heat

exchanger

failure

due

to

scale

buildup

from

hard

water

conditions

is

NOT

covered

by

warranty.

It

is

highly

suggested

that

a

scale

inhibitor

be

installed

before

the

cold

water

inlet

after

this

procedure

is

done.

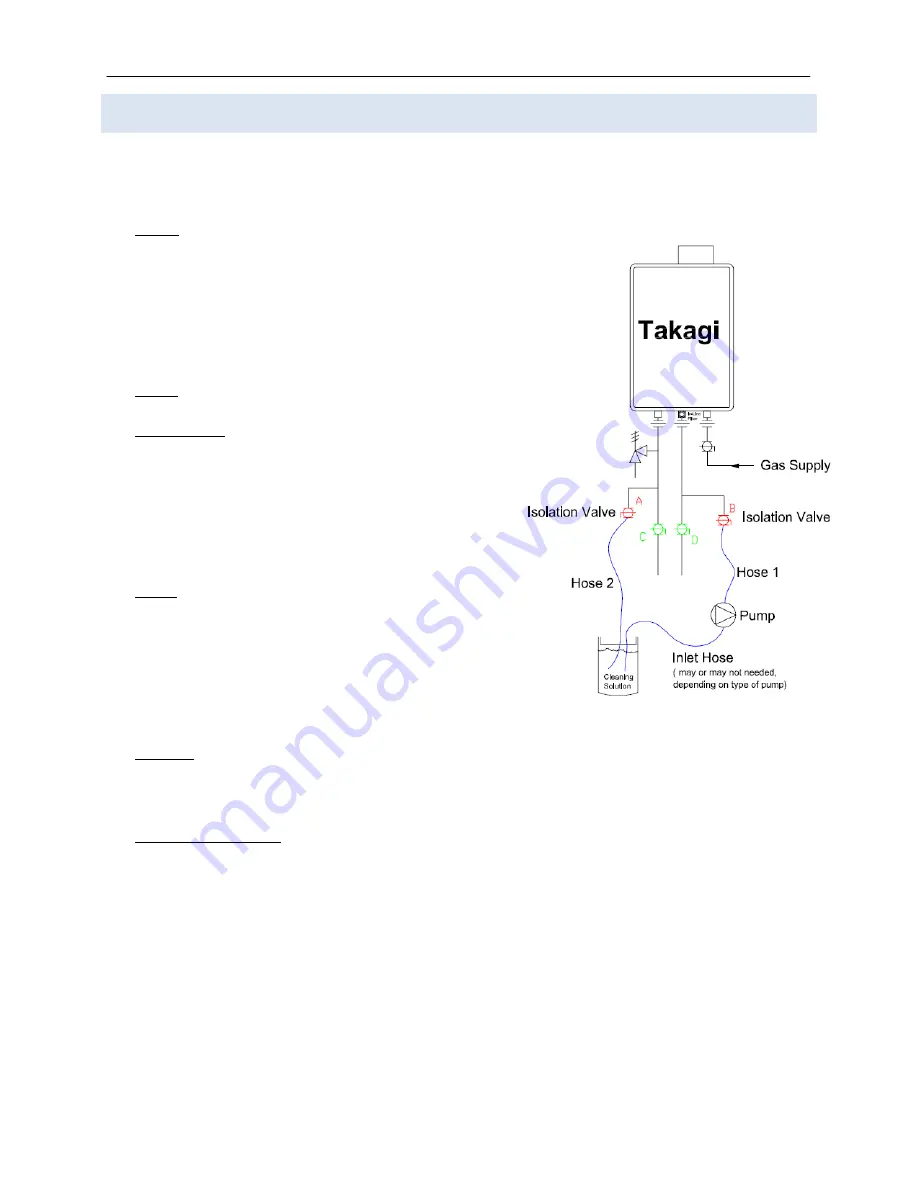

1)

TOOLS

‐

Gather

the

following

materials

together:

a.

Pump:

The

pump

should

provide

a

minimum

of

1GPM

through

the

heater

b.

Cleaning

Solution:

Food

grade

citric

acid,

food

grade

phosphorus

acid

c.

Water

hoses

d.

Bucket

2)

SETUP

‐

Disconnect

power

to

the

unit

3)

WATERLINES

–

Assumes

isolation

valves

with

drain

ports

are

installed

a.

Isolate

the

unit

by

closing

the

incoming/outgoing

water

isolation

valves

C

and

D.

b.

Connect

hoses/pump

to

the

drain

ports

of

the

isolation

valves:

Outlet

of

the

pump

to

valve

B,

and

another

hose

from

Valve

A

to

the

bucket.

4)

PUMP

–

a.

Fill

the

bucket

with

5

gallons

of

diluted

solution.

Dilution

ratio

depends

on

the

cleaning

solution

used.

b.

Place

the

pump

into

the

bucket

if

it

is

submersible,

or

use

an

inlet

hose

into

the

bucket

if

it

is

not

submersible.

5)

DESCALE

a.

Open

valves

A

and

B.

b.

Circulate

descaling

solution

through

the

unit

for

45

minutes.

6)

CLEANSE

THE

SYSTEM

–

Flush

the

chemicals

out

of

the

heat

exchanger

with

fresh

water.

a.

Close

valve

A

and

B.

b.

Open

valve

D

and

run

fresh

water

through

the

PRV

for

15

minutes.

c.

Clean

the

filter

after

flushing

the

unit

with

fresh

water.

d.

Once

the

unit

is

flushed

and

cleansed,

close

A

and

B,

open

C

and

D,

and

reconnect

power

to

the

unit.

321922

‐

000

Figure

41