AOS WPC - Tech Training

11 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

PRINCIPLES OF OPERATION

VF boilers do not have a gas orifice. The blower “pulls” gas from the gas valve into a Venturi

attached to the suction (inlet) side of the blower (page 12). As the speed of the blower is

increased the vacuum in the Venturi is also increased and more fuel gas and combustion air

is supplied to the burner. This is the basic principle of how a VF boiler modulates firing rate.

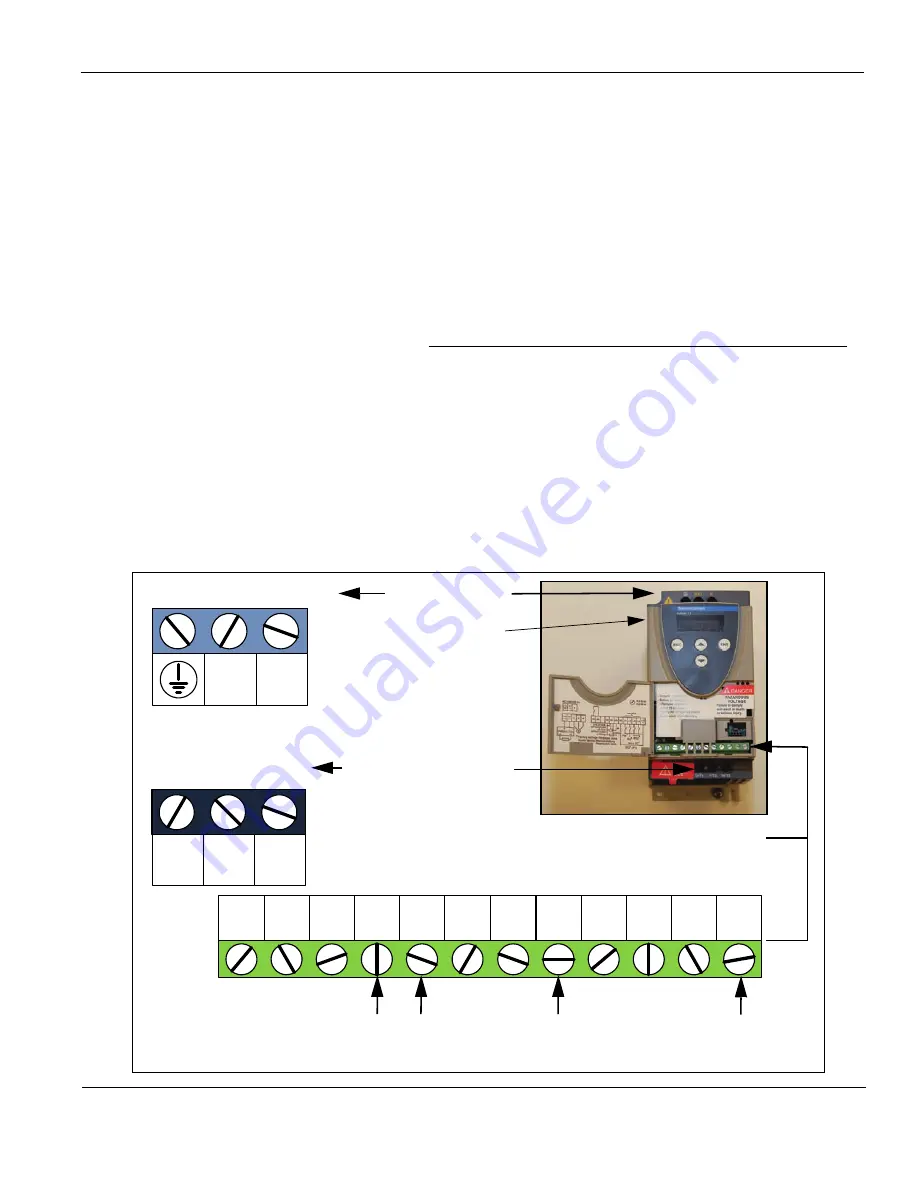

VFD and Blower Operation

VF boilers have a small circuit board (Daughter Board) attached to the MCB circuit board

(page 25). The MCB controls a VFD (variable frequency drive) through the J24 socket

connections on the Daughter Board (page 34). The VFD in turn powers the blower motor

directly. The VFD controls blower speed precisely by modulating the frequency (Hz) of the

power supplied to the blower motor. VFD output to the blower is a 3 Phase power supply.

Three conditions must be met before the VFD will start the blower:

1. 120 VAC is supplied to the VFD 120 VAC input.

2. The MCB closes an enable/disable circuit that enables VFD operation.

3. The MCB sends a 1-10 VDC instruction to modulate blower speed.

The DC voltage instruction sent by the MCB is directly proportional to blower speed - higher

DC voltage = higher (faster) blower speed.

The blower power frequency (Hz) is also directly proportional to blower speed - higher

frequency = higher (faster) blower speed. The output frequency is displayed on the VFD.

120 VAC input

Low Voltage Terminal Strip

1-10 VDC Instruction

Enable/Disable

W/T3

V/T2

U/T1

N

R/L1

RA

RC

+5V

AI1

0V

LI2

LI1

DO

+15

V

LI4

LI3

3 Phase Power

Variable Frequency

Output To Blower

Ground Hot Neutral

Black White Red

Blower Motor Wires

VFD

1-10 VDC Speed Instruction

Enable/Disable Circuit

See the important service notes on page 34

Output Frequency

Display