VF BOILER SERVICE MANUAL

AOS WPC - Tech Training

16 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

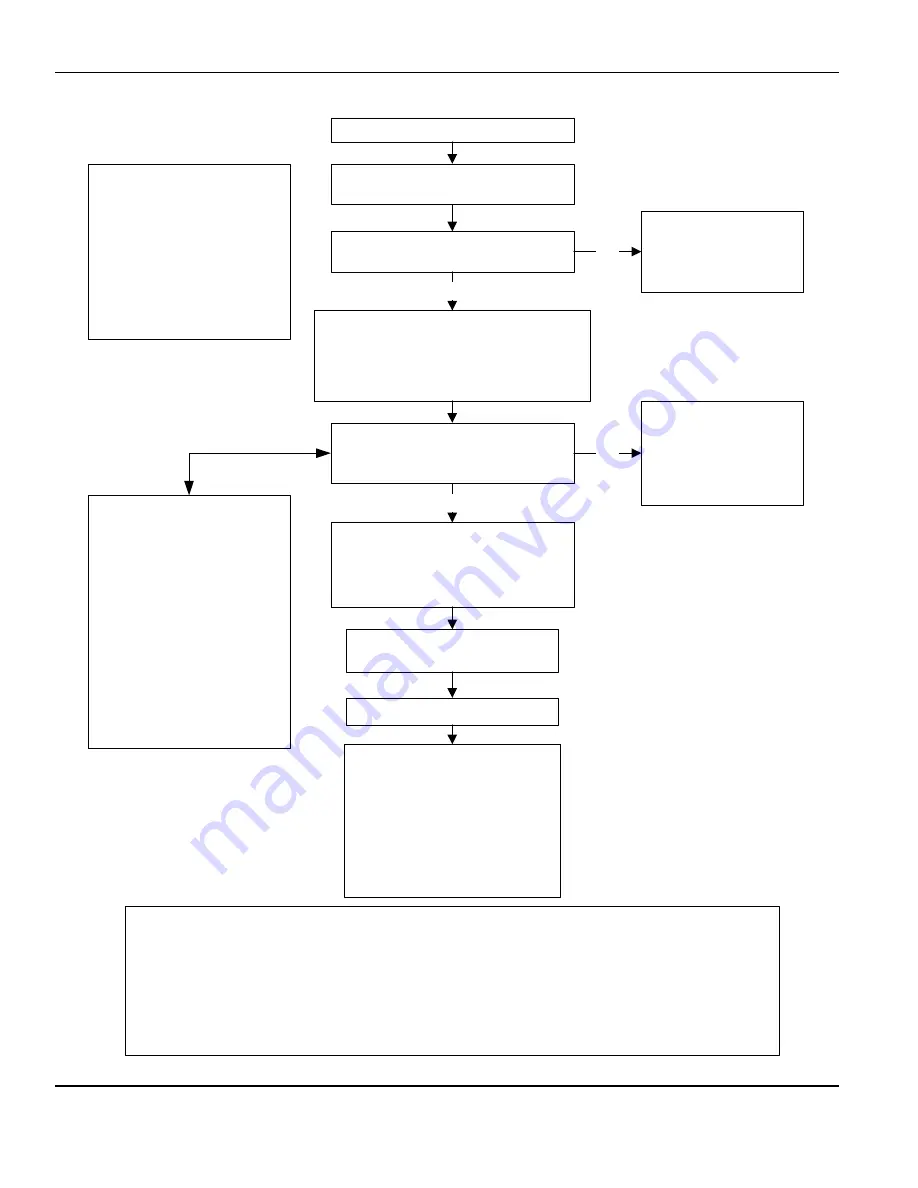

SEQUENCE OF OPERATION (CONT)

MCB Senses Minimum

2.7 AC Amps Through Ignitor

Gas Valve Is Energized

Fuel Gas Is Drawn Into

Blower Inlet By Venturi Assembly

Mixed With Combustion Air

Boiler enters Service Mode

and locks out. UIM displays

Igniter Stg1

Error message

Minimum Flame Sensing Current

2.5 µA (DC micro amps)

Detected From Flame Sensors

Water Is Heated To

Operating Set Point

Blower Runs 25 Seconds

Post Purge State – Shuts Off.

Pump Runs Continuous Or

Programmed Post Circulate

Period Shuts Off.

Boiler Goes Into Standby

MCB Energizes Ignitor

Ignition State – 18 Seconds

Previous Page

NOTE

The events shown in this flow chart

are in sequential order. The EMC

5000 is a multi-task control that

performs some functions

simultaneously. Only key events are

shown in order to provide a general

understanding of how the control

operates. Event timings can vary

depending on actual conditions.

SERVICE NOTE

VF boilers utilize two flame sensors.

One is positioned closer to the buner

than the second to enable flame

detection during low and high fire

conditions.

The wiring from the two flame

sensors is joined and connects to a

single connection point on the MCB

circuit board.

When the “Flame Stg1” error

message is displayed remove,

inspect, and clean both flame

sensors.

YES

NO

SERVICE NOTE:

In standby and running modes the system constantly monitors the signals and the internal

operation for faults.

Any detected fault will halt the heating sequence and shift the system to the service mode

where the detected fault will be displayed.

After 1 or 3 trials

(SW1 dip switch 2 setting)

Control enters Service Mode

and locks out. UIM displays

Flame Stg1

Error message

NO

Gas Valve Is De-Energized

MCB Instructs VFD (1-10 VDC)

To Modulate Blower Speed

According To Load Conditions

Throughout Heating Cycle

YES