VF BOILER SERVICE MANUAL

AOS WPC - Tech Training

20 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

POOR COMBUSTION - IGNITION PROBLEMS

If the high and/or low fire CO

2

combustion readings are not in accordance with the tables

shown on page 19, the CO readings are high, or if the boiler is experiencing ignition failure

or rough starting perform the following procedures:

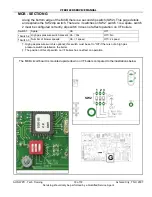

Adequate Combustion - Proper Venting

1. Ensure there is an adequate supply of fresh air for combustion and the boiler is vented

properly. DO NOT OVERLOOK THIS STEP. Lack of combustion air and improper

venting is often the root cause for poor combustion.

Direct Vent Installations:

If the boiler is direct vented ensure the intake air or the vent

pipe is not restricted and neither has exceeded the maximum 70 equivalent feet. Ensure

the vent and intake air terminations are positioned correctly so that vent gases are not

recirculating to the intake air termination. Installation note: each 90° elbow is equivalent

to 10 linear feet of pipe on VF boilers. If the boiler is in an equipment room with a door to

the outdoors, temporarily disconnect the intake air pipe and prop open the equipment

room door. Take combustion readings again to see if this corrects the problem.

Conventional Vent Installations:

If the boiler is using room air for combustion ensure

the vent pipe has not exceeded the 100’ maximum equivalent feet. Installation note:

each 90° elbow is equivalent to 10 linear feet of pipe on VF boilers. Ensure the fresh air

openings in the equipment room are adequately sized for the combined input Btu/hr

rating of all conventionally vented gas fired appliances in the room. If the boiler is in an

equipment room with a door to the outdoors - prop open the equipment room door. Take

combustion readings again to see if this corrects the problem.

General venting guidelines are shown here. Refer to the Instruction Manual that came with

the boiler for complete combustion air and vent installation information.

Direct Vent

Configurations

Conventional Vent

Configurations

Installation Note:

VF Boilers are classified as Category IV

appliances. AL29-4C vent material must

be used for the exhaust vent on all

installations.