AOS WPC - Tech Training

23 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

POOR COMBUSTION - IGNITION PROBLEMS (CONT)

Manifold Gas Pressure Check

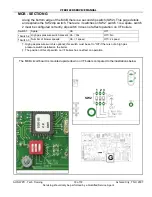

5. Attach Digital manometer to one of the manifold gas pressure taps on gas line between

the boiler’s 24 VAC gas valve outlet and the gas inlet on the Venturi as shown in the

images below. Recommend UEI model EM200 or equivalent. Manifold gas pressure on

VF boilers is a negative (vacuum) pressure. The lower the pressure (deeper the

vacuum) the higher the firing rate will be. Measure the manifold gas pressure with the

boiler firing in Max Mode and Min Mode (page 17). Manifold pressures should fall within

the ranges listed in the table below.

Service Note:

If the actual pressures observed during the test above are considerably

different (higher pressures - closer to a positive pressure) closely inspect all fittings and

flanges in the gas train between the outlet of the boiler's 24 VAC gas valve and the Venturi

assembly. See page 12. Reseal/repair any leaking connections - replace any worn or

damaged gaskets.

Disassemble the Venturi from the inlet connection at the blower (round flange) and the

intake air connection (square flange) - ensure the large “O” ring gaskets are not damaged

and seating properly.

Closely inspect the cone shaped restrictor inside the Venturi for any signs of damage or

wear. If the restrictor is missing, damaged, or visibly worn - replace the Venturi.

MANIFOLD PRESSURE

MAX MODE - 100% FIRING

MIN MODE - 25% FIRING

NATURAL GAS

-1.5" W.C. to -4.0" W.C.

-0.15" W.C. to -1.0" W.C.

PROPANE GAS

-1.5" W.C. to -4.0" W.C.

-0.15" W.C. to -1.0" W.C.

Venturi

Gas Valve

Gas Train

Shut Off Valve

Blower