1

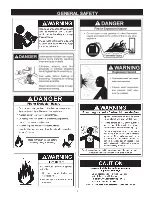

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

PRINTED 0411

320857-000

USER’S MANUAL

MODELS:

VB/VW-500, 750 AND 1000

SERIES 200/201

GAS-FIRED POWER BURNER

COPPER BOILERS FOR HYDRONIC HEATING

AND HOT WATER SUPPLY

•

Installation

•

Operation

•

Maintenance

•

Limited Warranty

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

Summary of Contents for VF VB 1000

Page 3: ...3 GENERAL SAFETY ...

Page 6: ...6 CONNECTION DIAGRAM ...

Page 7: ...7 ...

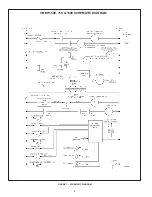

Page 8: ...8 Figure 1 SCHEMATIC DIAGRAM VB VW 500 750 1000 SCHEMATIC DIAGRAM ...

Page 9: ...9 LIGHTING OPERATION INSTRUCTIONS FOR MODELS VB VW 500 750 AND 1000 ...

Page 20: ...20 notes ...

Page 21: ...21 notes ...

Page 22: ...22 notes ...