6

A1-M-XL

2. MACHINE DESCRIPTION

2.1 WORKING PRINCIPLE

The manual Frame Assembling Machine A1-M-XL has been realized for the production of frames.

The A1-M-XL being of simple construction and extremely easy to use, makes it possible to join with absolute

precision any kind of moulding by using special steel A+ wedges to realize molding joints.

2.2 MAIN COMPONENTS

The main components constituting the machine are:

• Dual stage mechanical operating foot pedal that activate the vertical clamping device to allow a proper locking

of the mouldings and the nail insersion in different positions

• Magnetic pressure pads of several types, at quick replacement, to have the proper clamping of any profile

• Manual opening of the nail magazine for a very quick reloading

• Nail heads sizes 7, 10 and 15 mm.

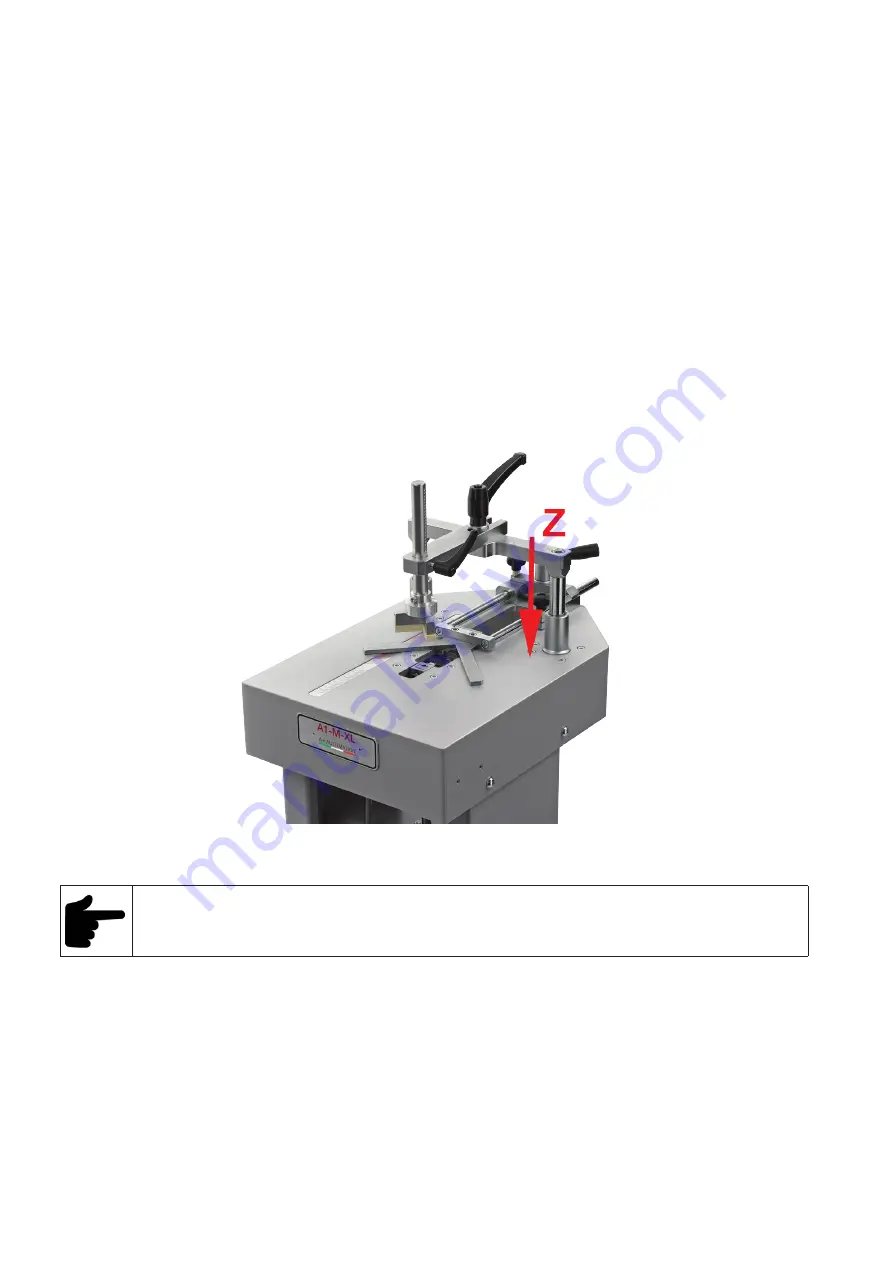

2.3 AXIS

- Z AXIS

Movement of vertical clamp.

Picture 2. 1 A - Movement directions

2.4 AMBIENT CONDITIONS IN THE INSTALLATION AREA

The installation area must have adequate environmental conditions.

The installation area must meet the following requisites.

• Adequate lighting to European standards (recommended 250÷650 lux)

• Well ventilated rooms

• Adequate relative humidity and temperature. The permitted temperatures go from 5° to 40° C, with a humidity

level not higher than 50% at 40° C or 90% at 20° C.

• The floor, as well as having an adequate load capacity for the machine weight, must be stable and levelled in

order to guarantee a correct support.

Summary of Contents for A1-M-XL

Page 3: ...3 A1 M XL...

Page 20: ...20 A1 M XL SCHEMES B Mechanic Schemes A1 M XL P R E L I M I N A R Y...

Page 21: ...21 A1 M XL SCHEMES B Mechanic Schemes A1 M...

Page 22: ...22 A1 M XL...

Page 23: ...23 A1 M XL...

Page 24: ......