16

A3-P

5. OPERATING MODES

5.1 OPERATORS

The machine has been designed to be used by only one operator.

The operator, as well as being adequately informed on the use of machinery, must possess skills and competence

adequate to the type of work to be performed.

Even after being adequately informed, during the first use, if necessary, simulate some operating maneuvers to

identify the controls, especially the ones for starting and stopping the machinery and their main functions.

How to operate in case of emergency , where to find the individual protection means and how to use them properly.

5.2 DESCRIPTION OF FUNCTIONS

The machine has only one possible operating mode: Manual operation by using the pneumatic foot pedal.

Press the foot pedal half way down to clamp the frames

Press the foot pedal all the way down to drive a wedge.

To assemble a frame junction, you must operate as follows:

1. Set the inserting positions by means of the fence locking clamps

2. Place the moulding on the work bench. Move the fence to the first inserting point.

3. Adjust the vertical clamp height and position

4. Adjust the frontal clamp position

5. Verify and adjust the proper working pressure, using the pressure regulator, according to the type of moulding

to be assembled are the mouldings to be assembled.

6. Press half way down on the pneumatic pedal to verify the proper position and clamping of the moulding.

7. Press the pedal all the way down to insert the Wedge. If you want to insert 2 or more Wedges, one upon the

other in the same position, you must release the pedal halfway and then press it all the way down again to

insert the second Wedge and so on.

8. Completely release the foot pedal

9. (If the assembly requires it) Move the moulding and the fence to the next inserting point and repeat the steps

6,7 and 8.

5.3 TIPS FOR QUALITY JUNCTIONS

a) Wedge types

In order to allow the machine to make excellent quality joints using different materials, it has been necessary to

manufacture different Wedges types for different uses (see attachment D).

Wedges can be classified in three different groups:

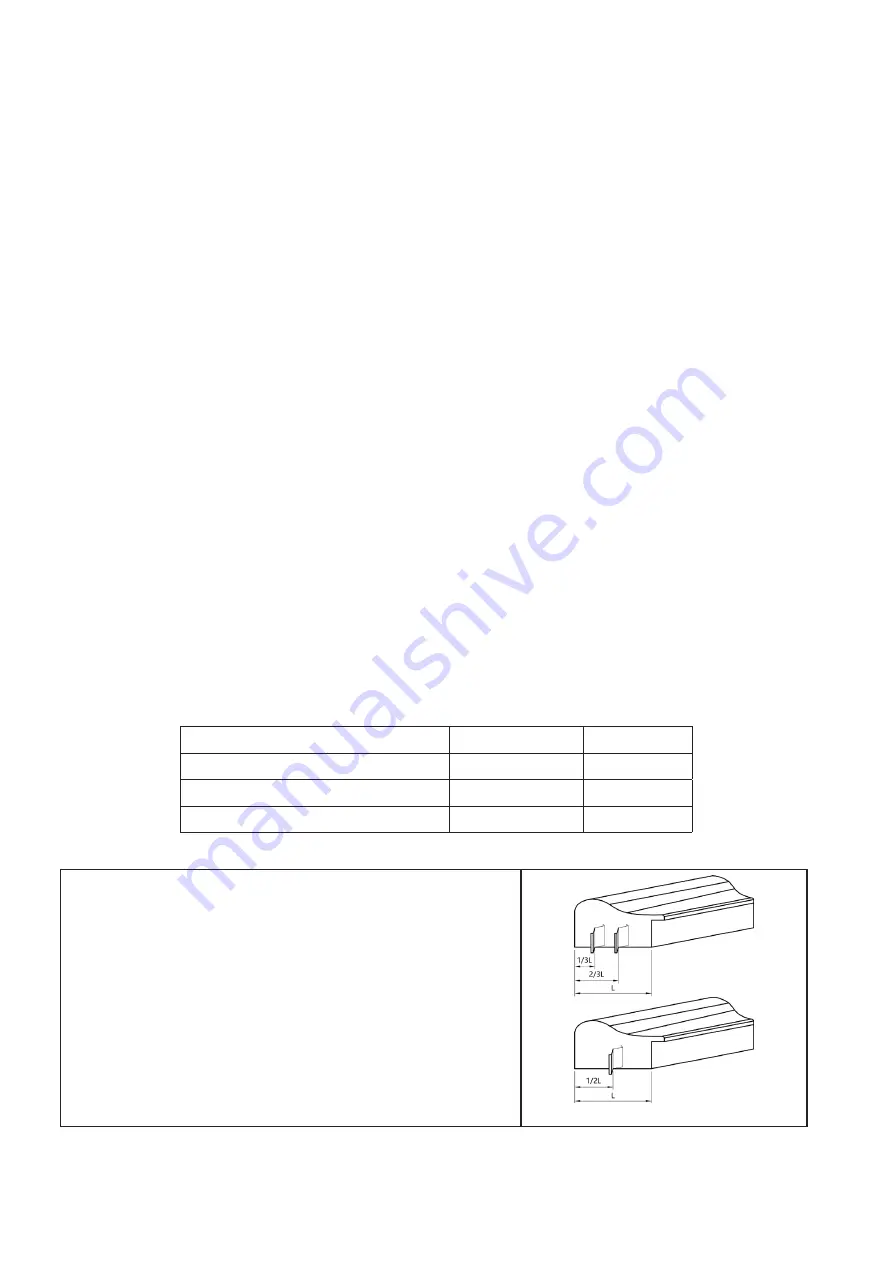

Material

Suggested code

Color Ref.

soft materials (wood, soft plastic)

SW

Green

for medium materials (wood, ...)

MW

Gray

for hard materials (wood, MDF, HDF)

HW

Red

b) Assembling positions

It is advisable to operate as follows in order to achieve the best results in terms of junction quality:

• Never drive Wedges near the external vertex. The minimum

recommended distance from the external vertex is at least 10 mm.

• When you want to make the junction using only one Wedge, the

most suitable position is in the middle of the moulding (see fig. 21)

• In case you want to insert 2 or more Wedges into each junction,

we recommend you to insert the most external one 1/3 from the

external vertex and the most internal one 1/4 from the internal

vertex (not less than 5mm).

picture 21

Summary of Contents for A3-P

Page 3: ...3 A3 P...

Page 22: ...22 A3 P SCHEMES A Mechanical Schematic...

Page 23: ...23 A3 P SCHEMES B Pneumatic Schematic...

Page 24: ...24 A3 P SCHEME C Plate locations...

Page 26: ...26 A3 P...

Page 27: ...27 A3 P...