TMC-4 Control Card

for Electric Actuators

Installation & Maintenance Manual

15

03/18/21

www.atcontrols.com

IOM08139 REVISION 01

4. Setup and Calibration

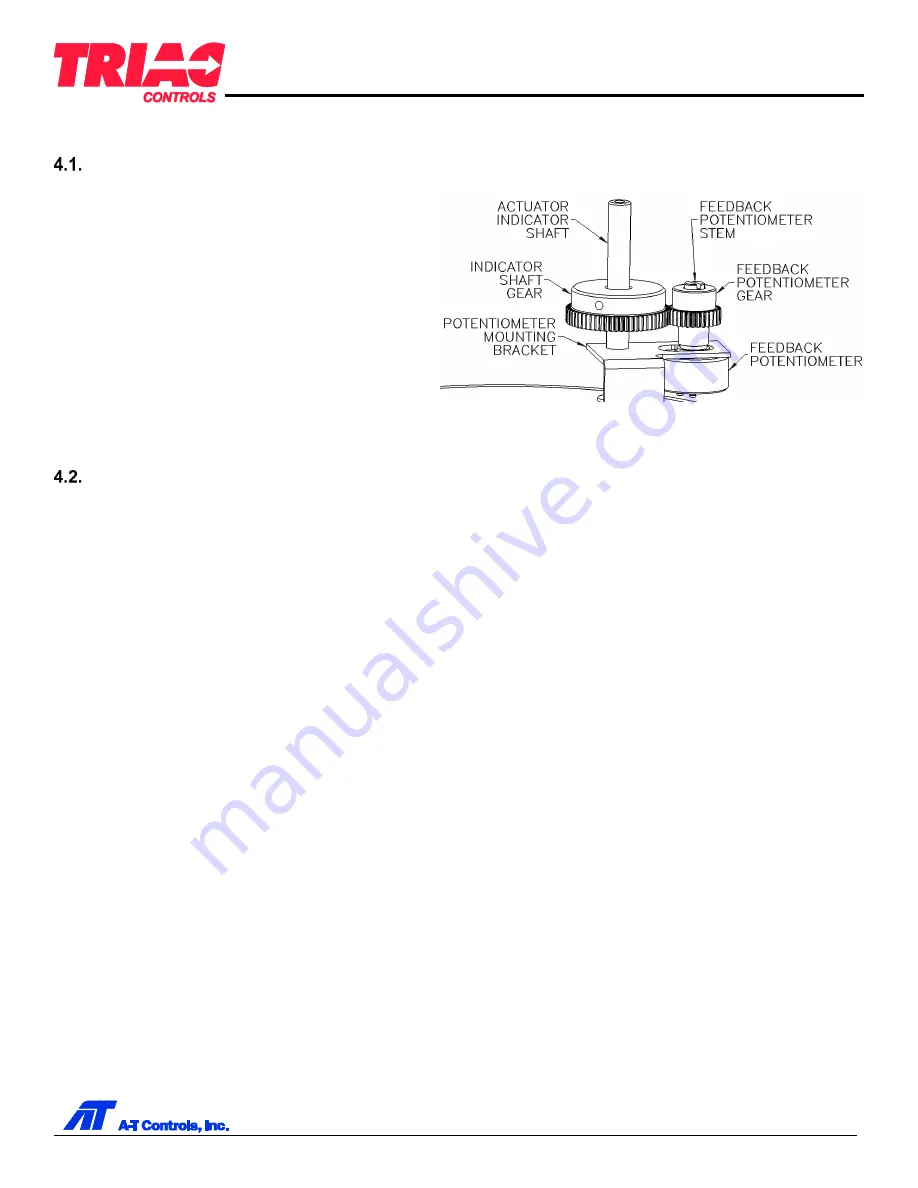

Feedback Potentiometer Adjustment

A feedback potentiometer is used to detect the position

of the actuator between the 0% to 100% limits for

modulating and proportional control applications. The

feedback potentiometer is coupled to the actuator

output indicator shaft by a set of gears.

The effective electrical angle of the potentiometer,

actuator rotation angle, and ratio of the feedback gears

determine how much of the potentiometer range will be

used for feedback. Typically, the actuator is moved to

the halfway position of the normal travel range, and the

feedback potentiometer is adjusted to the midpoint of its

effective electrical range to ensure operation within the

feedback potentiometer limits.

Analog Control

For when operating as proportional control actuator using some analog input.

1)

Set Supply Type Switch for AC or DC.

2)

Set “Motor Type” in

SYSTEM CONFIG

for AC or DC to match Supply Type Switch setting.

3)

Select and calibrate input command signal.

a)

Enter

COMMAND CONFIG

submenu.

b)

Select command signal type in “Command Type” setting.

c)

Connect command signal source to input terminals per appropriate wiring diagram.

d)

In “Calibrate Zero” setting, send 0% command signal and confirm.

e)

In “Calibrate Span” setting, send 100% command signal and confirm.

4)

Select and calibrate output feedback signal.

a)

Enter

FEEDBACK CONFIG

submenu.

b)

Select feedback signal type in “Feedback Type” setting.

c)

Connect feedback signal monitor to output terminals per appropriate wiring diagram.

d)

In “Calibrate Zero” setting, press [UP] or [DOWN] until feedback signal equals desired 0% feedback and confirm.

e)

In “Calibrate Span” setting, press [UP] or [DOWN] until feedback signal equals desired 100% feedback and

confirm.

5)

Set positioning method.

a)

Enter

POSITION CONFIG

submenu.

b)

Set to “Potent” in “Position Type” setting

c)

Adjust feedback potentiometer to center at 50% position.

i)

In “Calibrate Close Pos” or “Calibrate Open Pos”, press [UP] or [DOWN] to drive actuator to 50% position.

ii)

Rotate feedback potentiometer until display reads between 1900-2200, then tighten gears.

d)

In “Calibrate Close Pos”, press [UP] or [DOWN] to drive actuator to desired 0% position and confirm.

e)

In “Calibrate Open Pos”, press [UP] or [DOWN] to drive actuator to desired 100% position and confirm.