3

2

18

CORRECTION

FACTORS

FOR

USE

OF

GLYCOL

Glycol

rate

Freezing

point

(°C)

CCF

IPCF

WFCF

PDCF

10

%

‐

3,2

0,985

1

1,02

1,08

20

%

‐

7,8

0,98

0,99

1,05

1,12

30

%

‐

14,1

0,97

0,98

1,10

1,22

40

%

‐

22,3

0,965

0,97

1,14

1,25

50

%

‐

33,8

0,955

0,965

1,2

1,33

CCF:

Capacity

correction

factor

IPCF:

Input

power

correction

factor

WFCF:

Water

flow

rate

correction

factor

PDCF:

Pressure

drops

correction

factor.

The

water

flow

rate

and

pressure

drop

correction

factors

are

to

be

applied

directly

to

the

values

given

for

operation

without

glycol.

The

water

flow

rate

correction

factor

is

calculated

in

order

to

get

the

same

temperature’s

difference

that

would

be

obtained

without

glycol.

The

pressure

drops’

correction

factor

takes

into

account

the

different

water

flow

rate

obtained

from

the

application

of

the

water

flow

rate

correction

factor.

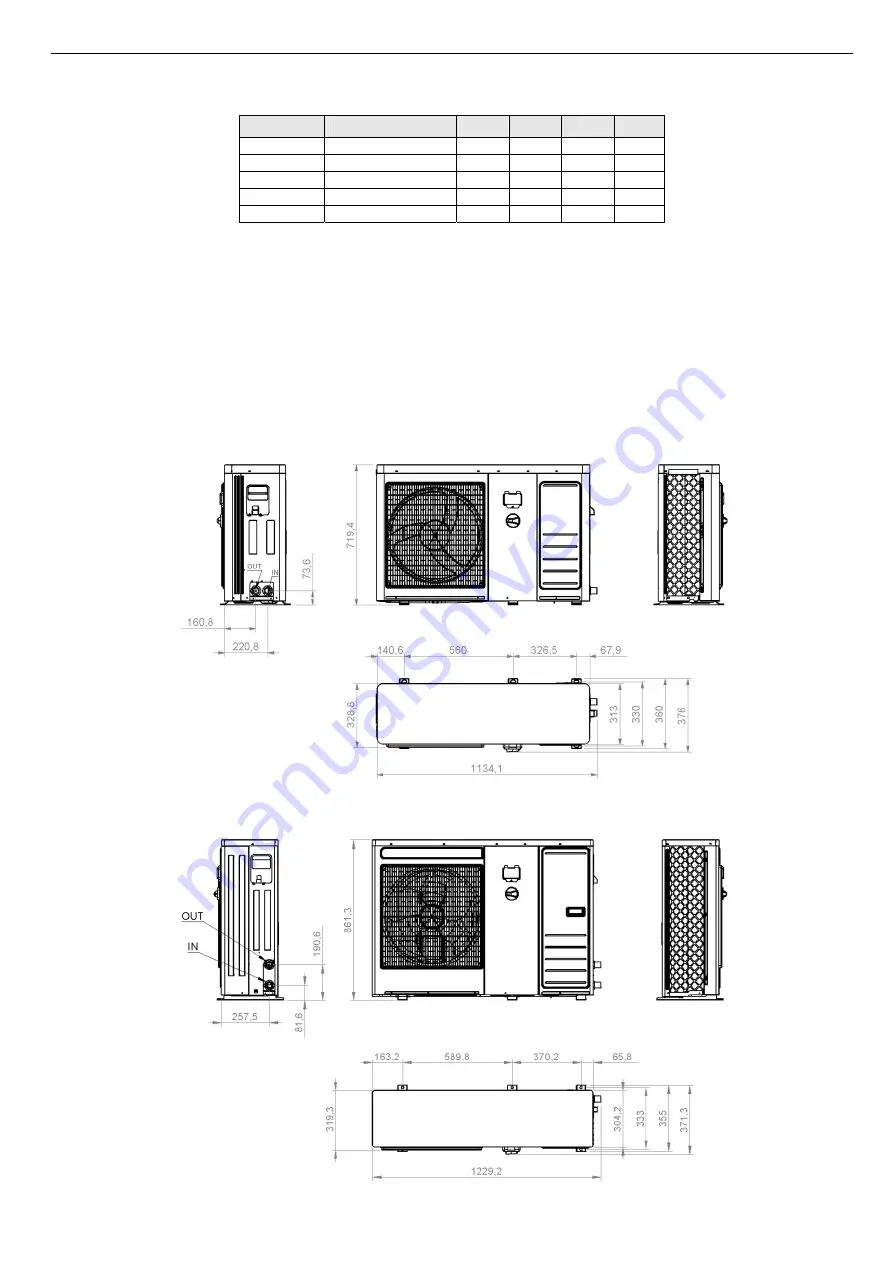

19

DIMENSIONS

19.1

MODELS

HPE

06

IN/OUT:

1”M

19.2

MODELS

HPE

09

IN/OUT:

1”M

Summary of Contents for HPE Series

Page 21: ......

Page 29: ...28 ...

Page 31: ...30 16 WATER PUMP CURVES 16 1 MODELS HPE 06 09 16 2 MODELS HPE 12 15 ...

Page 34: ...33 19 3 HPE 12 15 IN OUT 1 M ...

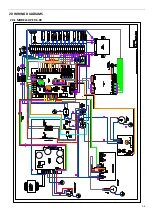

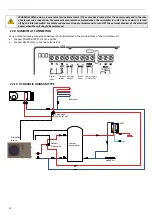

Page 35: ...34 20 WIRING DIAGRAMS 20 1 MODELS HPE 06 09 ...

Page 36: ...35 20 2 MODEL HPE 12 ...

Page 37: ...36 20 3 MODEL HPE 15 ...

Page 43: ...NOTE ...

Page 44: ...NOTE ...

Page 45: ...NOTE ...

Page 46: ...NOTE ...

Page 47: ......