5

/

20

IMMEDIATELY.

1.

Lifting

WARNING:

NEVER ATTEMPT TO LIFT THIS MACHINE USING THE SPINDLE OR ANY HANDWHEEL.

a). There is a M12 Eye Bolt in the top of the spindle housing. Be sure the eye bolt is down tight.

b). Using the eye bolt as a lifting point, place the machine in its predetermined location and

secure using the three mounting lugs on the machine base.

2. Thoroughly clean the machine, using a soft cloth and an approved solvent, to remove any

preservative coating.

WARNING:

DO NOT use lacquer thinner.

3. Be sure all switches are in the OFF position.

CAUTION:

DO NOT attempt to test or operate this machine until you are completely familiar with

the functions of all of the controls and switches.

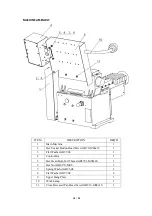

DISC TRUING ATTACHMENT

The disc truing attachment can be mounted in any one of three positions

(See Figure 4), depending on the diameter of the disc. The maximum travel

of the slide in any position is 4”.

1). Select the appropriate threaded hole in the feed slide plate and screw

one end of the clamp stud into it.

2). Place one of the slotted holes of the disc attachment over the stud.

Add the spacer and the washer. (Figure 5) Secure the attachment using

the clamp handle.

Note:

Final location of the disc attachment can be made after the disc

rotor to be machined has been installed.

DRUM TRUING ATTACHMENT

The drum truing attachment can be mounted in any one of three locations

depending on the diameter of the drum.

1). Select the appropriate threaded hole in the feed slide plate and screw

one end of the clamp stud into it.

2). Place the tool bar tube over the clamp stud, add the washer and secure

using the clamp handle. (Figure 6)

NOTE:

Final location of the drum attachment can be made after the

drum has been installed.

ARBOR ATTACHMENT

The standard arbor, mounts quickly to the spindle receptacle using a

threaded draw bar and hand wheel. (Figure 7)

1. Insert the arbor, threaded hole first, into the spindle receptacle at

the left end of the spindle housing, carefully make mark.

NOTE:

Make certain mating surfaces on the arbor and spindle are clean and free of nicks and

gouges. The smallest nick or scratch can cause incorrect drum or rotor alignment resulting in

inaccurate resurfacing.

WARNING:

Never loosen or attempt to remove arbor with a disc or drum mounted.

2. Turn the draw bar hand wheel until the arbor is drawn up tight.

NOTE:

To remove the arbor, give the draw bar hand wheel a quick counter-clockwise turn to

loosen. Continued counter-clockwise rotation frees the draw bar from the arbor allowing the

Summary of Contents for C9372

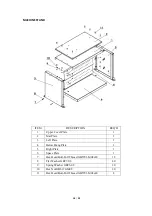

Page 13: ...13 20 Cross Feed Feed Slide Assembly ...

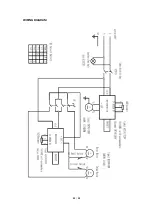

Page 20: ...20 20 WIRING DIAGRAM ...