98

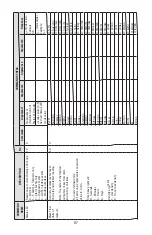

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNT

AX

Command

Argument 1

Argument 2

Argument 3

Argument 4

Response

lb/hr

U: lb/hr

lb/day

U: lb/day

oz/sec

U: oz/sec

oz/min

U: oz/min

NuL/min

U: NuL/min

Nml/sec

U: NmL/sec

Nml/min

U: NmL/min

Nml/hr

U: NmL/hr

NL/sec

U: NL/sec

NL/min

U: NL/min

NL/hr

U: NL/hr

NL/day

U: NL/day

Nm3/min

U: Nm3/min

Nm3/hr

U: Nm3/hr

Nm3/day

U: Nm3/day

Nf3/sec

U:Nf3/sec

Nf3/min

U:Nf3/min

Nf3/hr

U:Nf3/hr

Nf3/day

U:Nf3/day

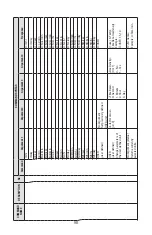

USER

(user defi

ned)

No Argument

Set previously defi

ned

USER unit

U:USER

USER

(user defi

ned)

Change parameters of

the user defi

ned unit

<k-factor value>

[>0.0]

<T

ime Base>

0- Second

1- Minute

2- Hour

3- Day

<Use Density>

[0 or 1]

0 – No

1 – Y

es

U:user

, K-Factor

,

T

imeBase,UseDensity

Example:

U:USER,1.5,1,0

No Argument (status)

Returns currently

selected units.

U:<EU name>

Example: U:SmL/min

Summary of Contents for DPC

Page 6: ...2...

Page 120: ...116 APPENDIX I COMPONENT DIAGRAM Top Component Side...

Page 121: ...117 Bottom Component Side...