the top of the valve will indicate a fully OPEN valve condition.

During normal operation the valve remains in the last position as it is de-

energized. After powering up, the valve will be automatically closed with-

in the first 10 seconds and after that resumes control operation.

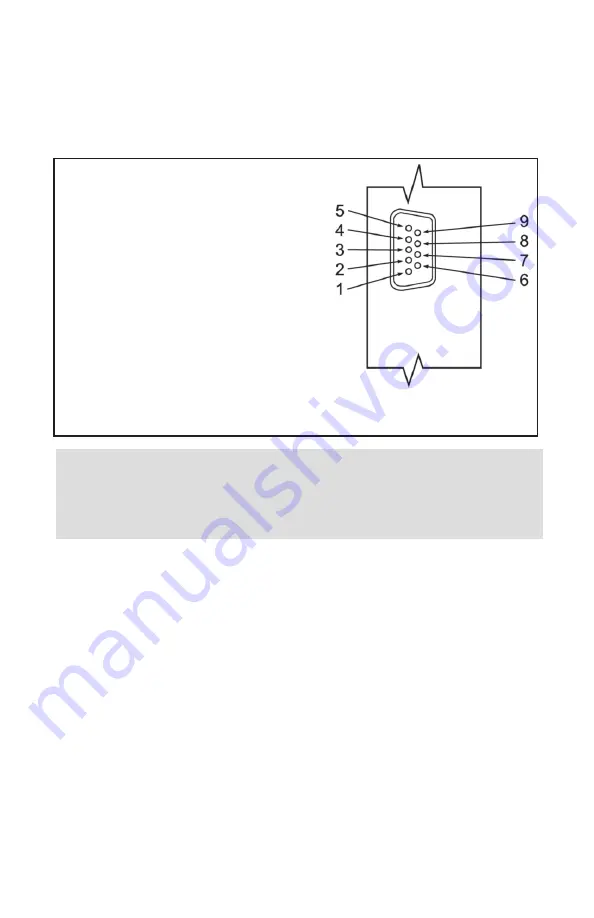

FIG.b-1

SMV 9-PIN “D” CONNECTOR CONFIGURATION

WARNING

: DO NOT CONNECT 24 Vdc POWER SUPPLY UNLESS YOUR

SMV VALVE WAS ORDERED AND CONFIGURED FOR 24Vdc VOLTAGE

(SEE POWER REQUIREMENTS LABEL). DO NOT APPLY TO THE

DIRECTION CONTROL SIGNAL (PIN 8) VOLTAGE MORE THAN 12 Vdc

Important Notes:

In general, "D" Connector numbering patterns are standardized. There

are, however, some connectors with nonconforming patterns and the

numbering sequence on your mating connector may or may not coincide

with the numbering sequence shown in our pin configuration table above.

It is imperative that you match the appropriate wires in accordance with

the correct sequence regardless of the particular numbers displayed on

your mating connector.

Make sure power is OFF when connecting or disconnecting any cables in

the system.

The power input is protected by a 1600mA M (medium time-lag) reset-

table fuse. If a shorting condition or polarity reversal occurs, the fuse will

cut power to the valve circuit. Disconnect the power to the unit, remove

the faulty condition, and reconnect the power.

3

,

PIN FUNCTION

1

(unassigned).

2

Common, Power Supply Minus.

3

Valve Off Control (12V CMOS Low active).

4

Speed control signal (analog 0-2.5 Vdc).

5

(unassigned).

6

Common for Speed control.

7

Valve PURGE control (12V CMOS Low Active).

8

Direction control signal (digital 12Vdc CMOS logic).

9

+12 Vdc (+24Vdc optional) Power Supply Plus.