AD-4411

8

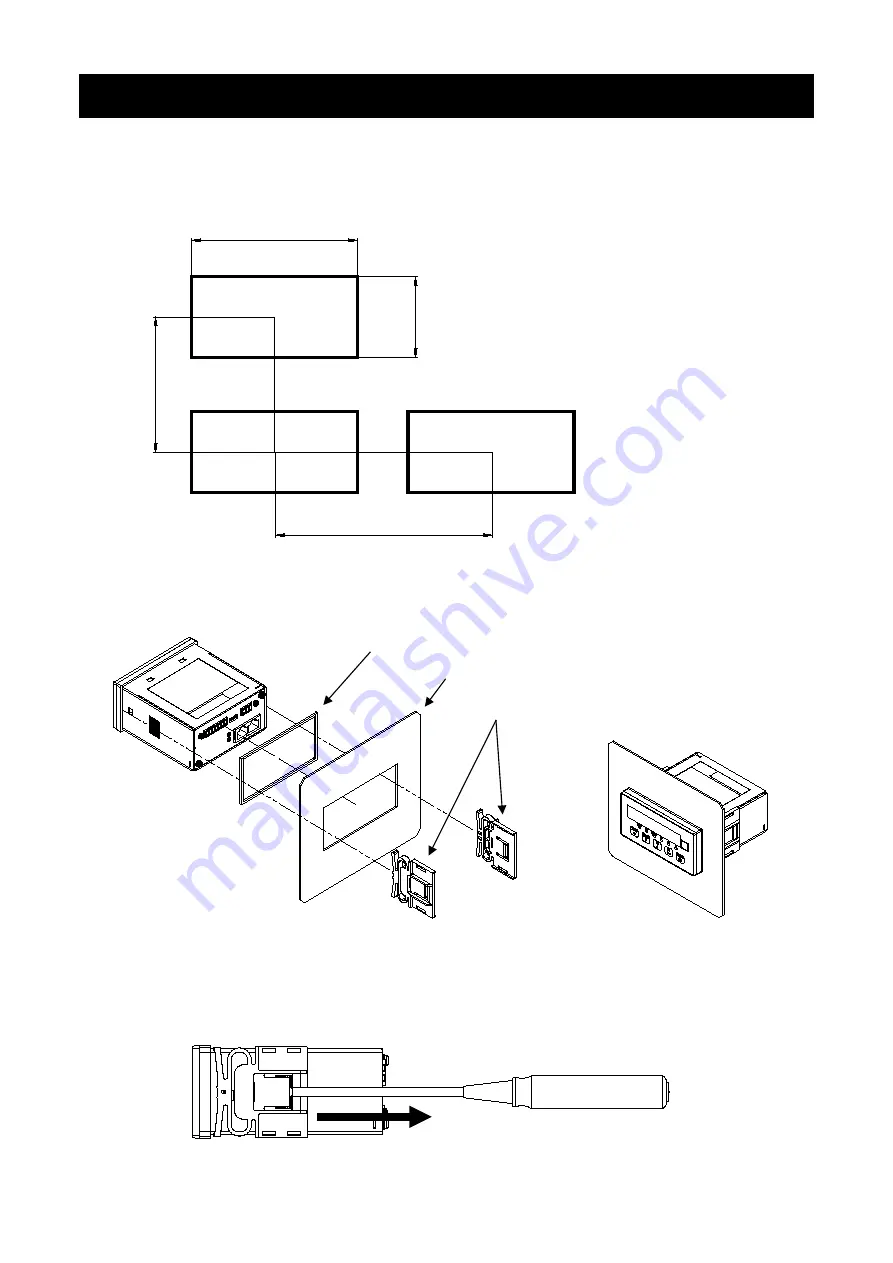

3. Installing to the control panel

3.1. Installing the indicator to the control panel

Make a hole in the control panel of the dimensions shown in the figure below. When installing more than one

indicator, make sure there is sufficient space around each unit for heat dissipation.

Attach the waterproof packing to the main body, then insert the main body into the control panel from the front.

Fit the left and right mounting brackets into the grooves of the case and slide them all the way into the panel.

3.2. Removing the indicator from the control panel

While lifting the latch of the panel mounting bracket from the case using a flat head screwdriver or similar tool,

slide the bracket towards the rear of the case.

92

+0.8

0

45

+0

.6

0

120

75

Panel thickness: 1.6 to 3.2

Unit: mm

Control panel

Waterproof packing

Panel mounting brackets

Summary of Contents for AD-4411

Page 1: ...1WMPD4004595 ...