AD4329A-DLC

Page 15

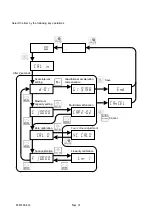

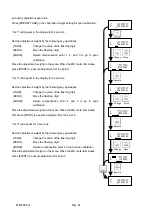

6. Calibration

Calibrate the AD4329A-DLC so that it can properly

convert the signal from the load cell to a mass value.

Set or execute the following items required for calibration.

・

Scale interval (resolution) setting

・

Maximum capacity setting

・

Four corner adjustment

・

Zero calibration

・

Span calibration

・

Linearity calibration

(if necessary)

・

Gravity acceleration compensation (if necessary)

Refer to "13.3 CF-function setting method” regarding setting of decimal point position (CF-000) and units (CF-001).