52

place. This will be detrimental to the

operation of the pump.

Inspect the cover O-ring and replace if

necessary.

Replace the permanent strainer into the

fitting body, once the temporary strainer is

removed.

Replace the cover into the body. Ensuring

that the strainer is properly seated, tighten the

cover bolts diagonally, evenly and firmly.

Flo-Trex Combination Valve

Introduction

The Flo-Trex combination valves are

designed for installation on the discharge side

of centrifugal pumps, and incorporate three

functions in one valve:

1.

Drip-tight shut-off valve

2.

Spring closure design, Non-slam check

valve

3.

Flow throttling valve

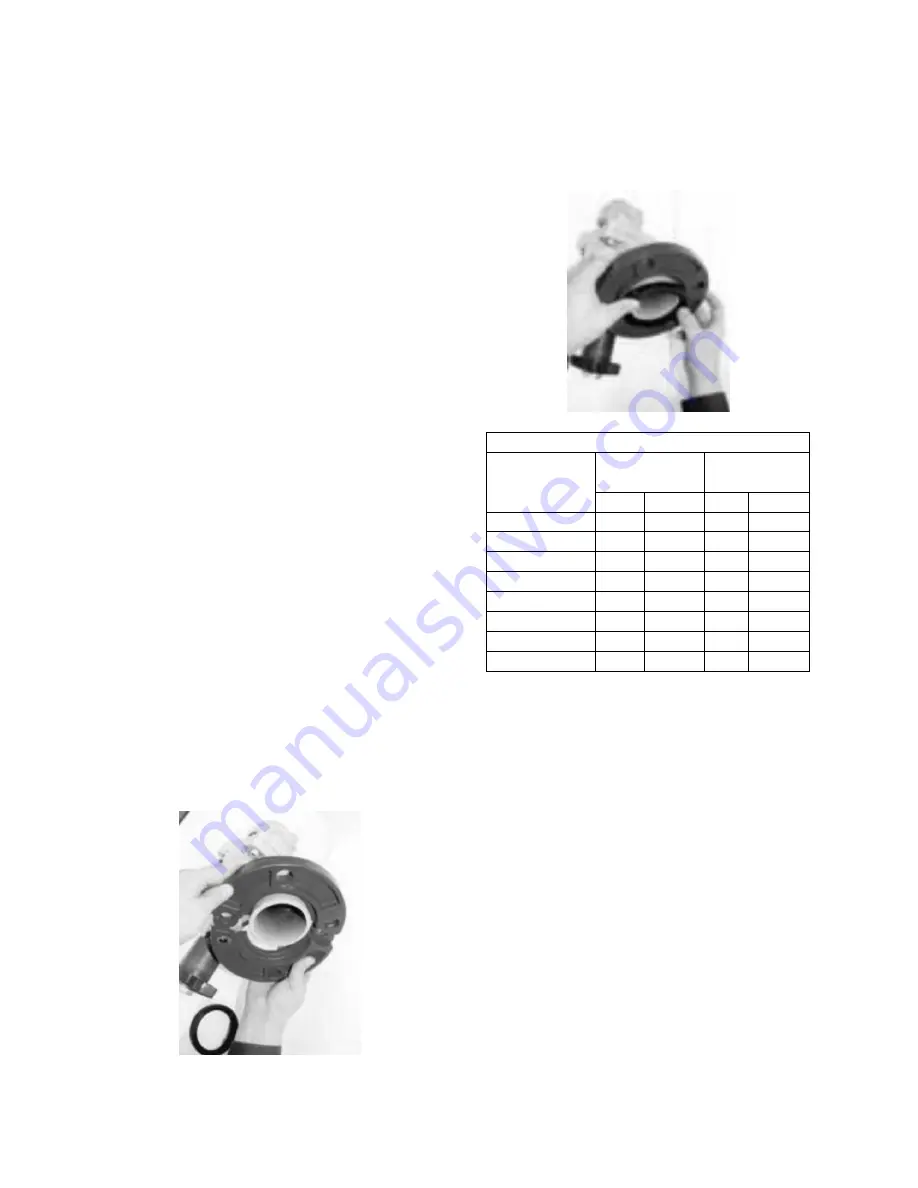

Armgrip Flange Adapter Installation

1.

Position the two halves of the Armgrip

flange adapter on the valve body ensuring

that the lugs on each half of the flange

adapters are located between the anti-

rotation lugs on the valve body (as

shown).

Insert two bolts of specified size (Table A1)

to secure the halves of the flange adapter to

the valve body (as shown).

Table A1. Armgrip Flange Adapter Details

Valve Size

125 psi/150 psi 250 psi/300 psi

Ductile Iron Bolt Ductile Iron Bolt

No.

Size

No.

Size

2-1/2

4

5/8

8

3/4

3

4

5/8

8

3/4

4

8

5/8

8

3/4

5

8

3/4

8

3/4

6

8

3/4

12

3/4

8

8

3/4

12

7/8

10

12

7/8

16

1

12

12

7/8

16

1-1/8

The gasket cavity should face out to the

adjoining flange.

2.

Lubricate the inner and outer diameter of

the gasket with the lubricant provided or

a similar non-petroleum based water

soluble grease.

3.

Press the gasket firmly into the flange

cavity ensuring that the sealing lip is

pointed outward. When in place, the

gasket should not extend beyond the end

of the pipe (as shown).

Summary of Contents for LN Series

Page 49: ...49 ...

Page 50: ...50 ...

Page 57: ...57 Pressure Temperature Limits Flo Trex Cross Section ...

Page 62: ......