53

4.

Position the adjoining flange or the pipe

to the Armgrip flange adapter and install

the remaining bolts. The two locking

bolts should be tightened first in order to

position the flange correctly.

Note: Care should be taken to ensure that

the gasket is not pinched or bent between

flanges.

5.

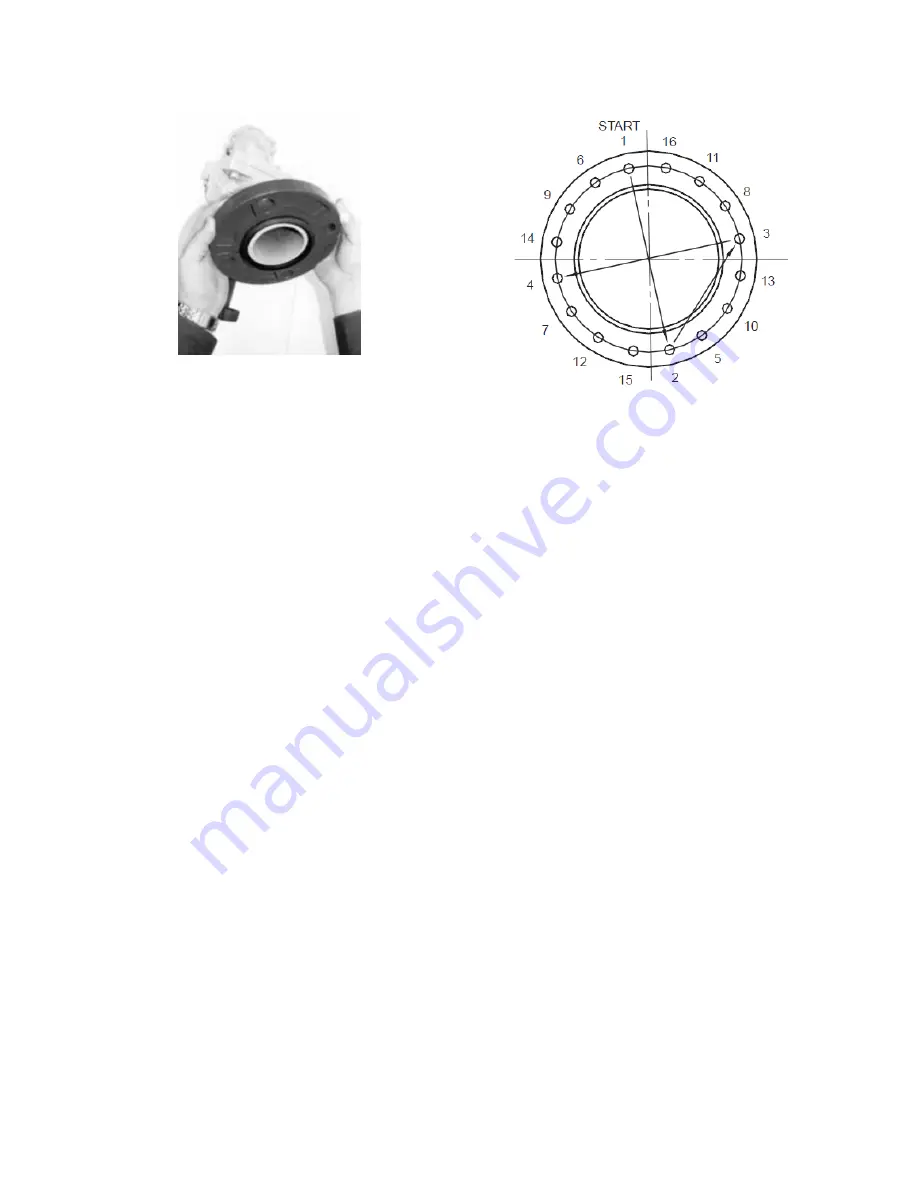

Tighten remaining nuts evenly by

following bolting instructions, so that the

flange faces remain parallel (as shown in

the figure labeled Recommended Bolt

Tightening Procedure). Flange bolts

should be tightened to 70 ft-lbs torque

minimum to assure firm metal to metal

contact. When raised face flanges are

used, there will be a gap between the

faces of the outer diameter.

6.

Flange gaskets are not interchangeable

with other mechanical pipe couplings or

flange gaskets.

Recommended Bolt Tightening Procedure

Field Conversion (Straight to Angle

Pattern Valve:

1.

Open valve at least one complete turn.

2.

Remove the body bolts from valve body

using Allen Key

3.

Rotate one half of the valve body 180°

making sure the lower valve seat and O

ring stay in position. Inspect the O ring

for any cuts or nicks and replace if

necessary.

4.

Replace body bolts and torque evenly to

70 ft-lbs.

Summary of Contents for LN Series

Page 49: ...49 ...

Page 50: ...50 ...

Page 57: ...57 Pressure Temperature Limits Flo Trex Cross Section ...

Page 62: ......