72

Capacity

Maintenance Instructions

To clean strainer remove the bottom plug and

pull out strainer.

Adjustment

To adjust pressure setting, loosen the lock nut

and turn the adjusting bolt clockwise to

increase pressure, counter clockwise to

decrease pressure.

Note:

Use a pressure gauge downstream to

adjust and verify the pressure setting.

Troubleshooting

High System Pressure

If the downstream system pressure is higher

than the set pressure under no flow

conditions, the cause could be thermal

expansion, pressure creep or dirt/debris on

the seat. Thermal expansion occurs whenever

water is heated in a closed system. The

system is closed when supply pressure

exceeds 150 psi, or a check valve or backflow

preventer is installed in the supply piping. To

determine if this is the result of thermal

expansion, try briefly opening the cold water

tap. If the

increased pressure is caused by

thermal expansion, the pressure will

immediately be relieved and the system will

return to the set pressure.

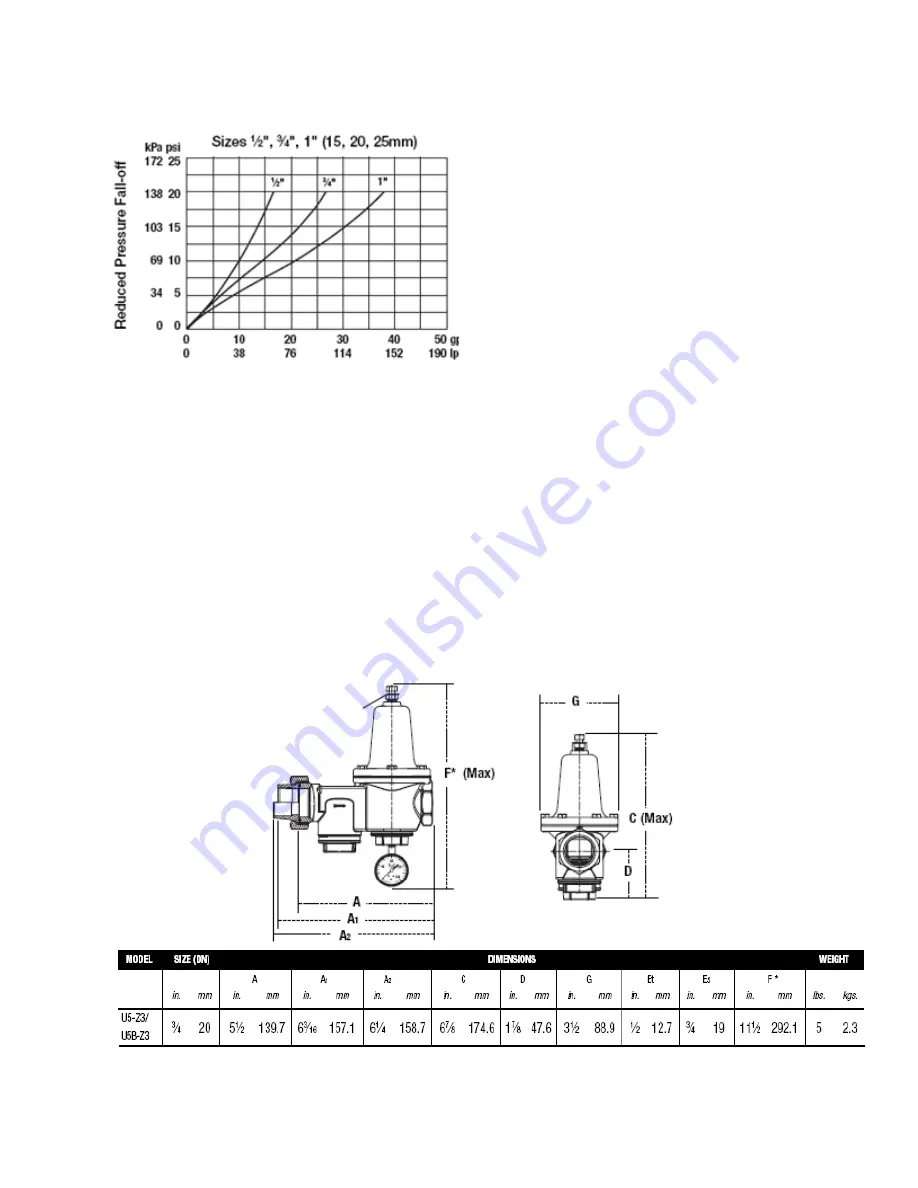

Dimensions-Weights:

Summary of Contents for LZ Series

Page 2: ......

Page 27: ...27 Figure 6 Concrete Pad Mounting with Dimensions Figure 7 LZ Base ...

Page 36: ...36 Figure 17 Typical Flue Vent Piping ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 95: ...95 Flo Trex Cross Section ...