80

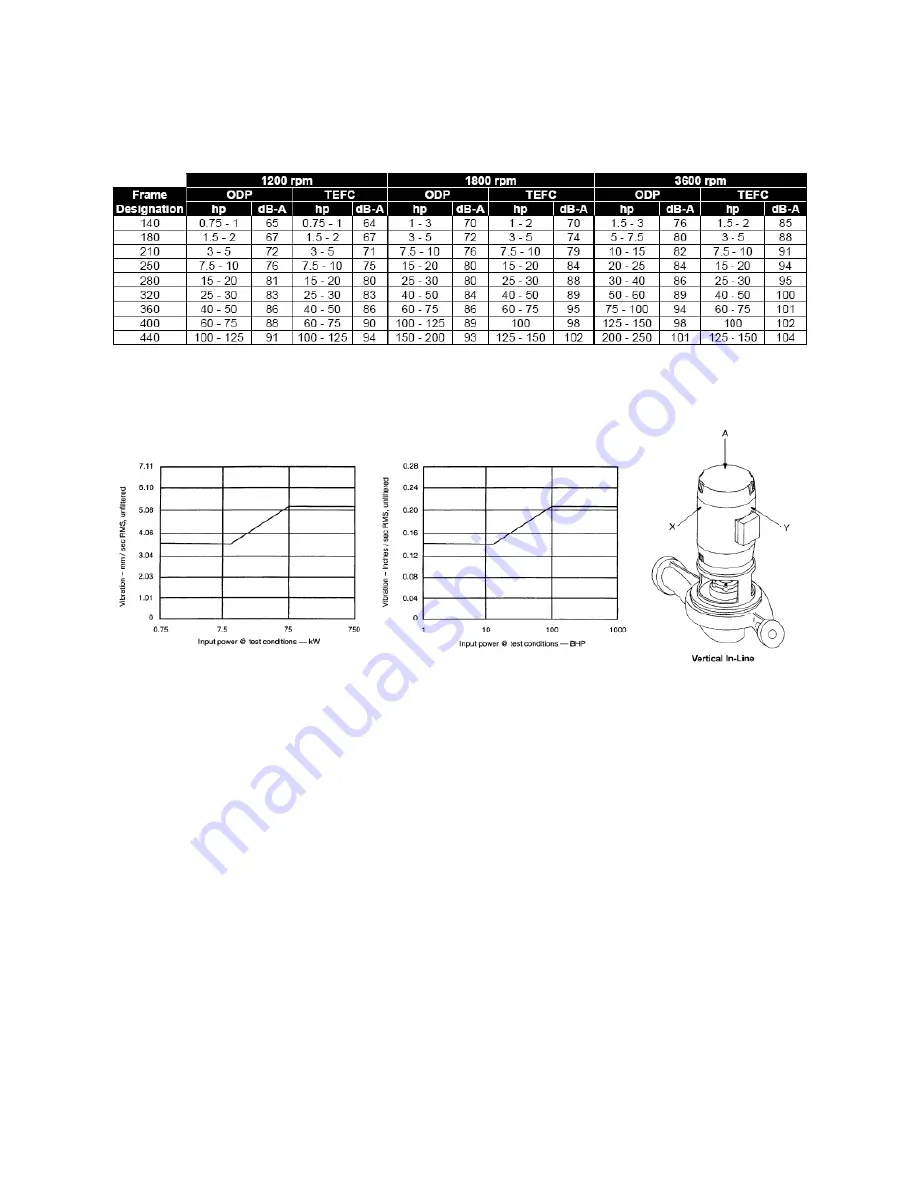

Noise Levels

Estimated Pumping Unit Sound Power Level, Decibels, A-Weighted, at 1 m (3 ft.) from unit.

Vibration Levels

Vertical In-Line pumps are designed to meet vibration levels set by Hydraulic Institute Standard

HI Pump Vibration 9.6.4. Standard levels are as detailed below:

Dual Pump Specific Information

Dual Pump Flapper Valve Operating

Instructions

This unit is fitted with internal valves to allow

isolation of one pump for service and to

automatically prevent recirculation of the

flow when only one pump is running.

Procedure for Parallel or Stand-By

Pumping

Discharge and suction valve stems should be

locked in the center position. This is

indicated by both locking handles in the

vertical position and the center pin of the

locking arms (4) locked by the handles. This

procedure allows the discharge flapper valves

to pivot freely and locks the suction valve

firmly in the center position.

Procedure for Isolation of One Side

1.

Stop the pump to be serviced.

2.

Close and lock the suction and discharge

valves: as per instructions below.

3.

Ensure seal flush line interconnection

valve is closed and drain the isolated

casing.

4.

Service isolated pump as required.

Procedure for Starting the Pump after

Servicing

1.

Ensure serviced pump is fully re-

assembled including all seal flush lines

and drain plugs.

2.

Fill the dry casing with system fluid by

opening

the

seal

flush

line

interconnecting valve and the air vent

fitting.

Summary of Contents for LZ Series

Page 2: ......

Page 27: ...27 Figure 6 Concrete Pad Mounting with Dimensions Figure 7 LZ Base ...

Page 36: ...36 Figure 17 Typical Flue Vent Piping ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 95: ...95 Flo Trex Cross Section ...