8

ELECTRICAL

Verify the unit data plate voltage agrees with the power

supply. Route power and control wiring through the

utility entry. Do not run power and signal wires in the

same conduit. Connect power according to the (unit

specific) wiring diagram provided.

Protect the branch circuit in accordance with code re-

quirements. Control wires should not be run inside the

same conduit. The unit must be electrically grounded in

accordance with the current National Electric Code,

ANSI / NFPA No. 70. In Canada use current C.S.A.

Standard C22.1 Canadian Electric Code Part 1.

Power wiring is to the unit terminal block or main

disconnect. All wiring beyond this point has been done

by the manufacturer and cannot not be modified without

effecting the unit's agency / safety certification.

INSTALLATION continued

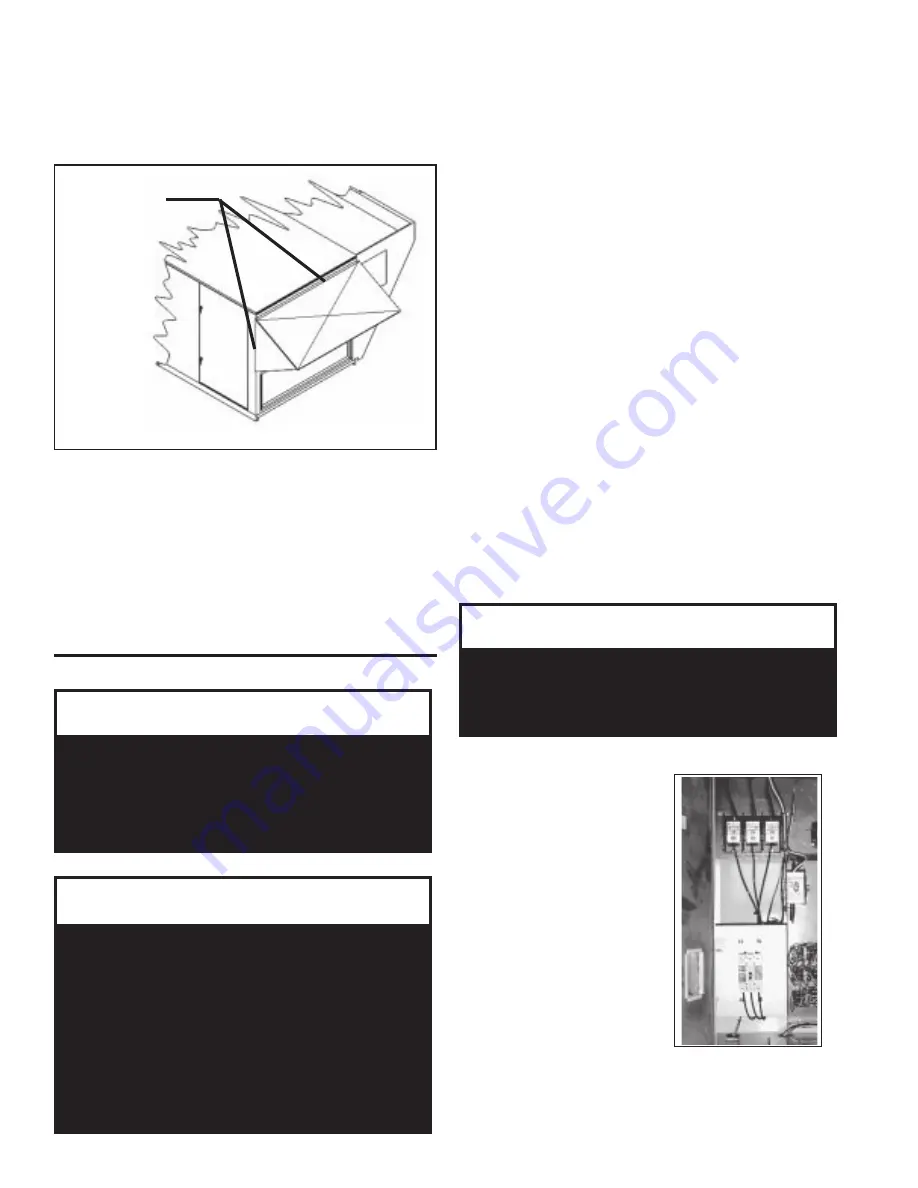

OUTSIDE AIR HOOD

CAUTION: Prior to unit operation, the outside air hood

must be opened as shown below:

AIRFLOW IS TO BE ADJUSTED AFTER

INSTALLATION TO OBTAIN AN AIR

TEMPERATURE RISE WITHIN THE RANGE

SPECIFIED ON THE RATING PLATE.

DUE TO JOB SPECIFICATION REVISIONS,

IT MAY BE NECESSARY TO ADJUST OR

CHANGE THE SHEAVE OR PULLEY TO

OBTAIN THE DESIRED AIRFLOW

AT THE TIME OF INSTALLATION.

Remove shipping screws from each side of the hood in the

"closed" postion. Lift hood to the "open" position, seal

flange and secure with sheet metal screws.

Air hoods may vary according to unit size and options.

The illustration shown is for practical guidelines for all

outside air hoods.

Outdoor air intake adjustments should be made accord-

ing building ventilation or local code requirements.

NOTE: All units are factory

wired for 208 / 230, 460 or

575 volt. If unit is to be

connected to a 208v supply,

the transformer must be

rewired for 208v service.

For 208v service interchange

the yellow and red conductor

on the low voltage control

transformer.

RED - BLK 208 volt ;

YEL - BLK 230 volt.

▲

!

CAUTION

START-UP TECHNICIAN MUST CHECK BLOWER

MOTOR AMPERAGE TO ENSURE THAT THE

AMPERAGE LISTED ON THE MOTOR NAMEPLATE

IS NOT EXCEEDED.

▲

On three phase units the rototation must be

checked on ALL MOTORS AND COMPRESSORS.

SCROLL COMPRESSORS ARE DIRECTIONAL.

Rotation must be checked on start-up by a

qualified service technician using

suction and discharge gauges.

Scroll compressors will FAIL if run in the wrong

direction. Blower and condenser rotation

should be checked and only be altered if

necessary at the power connection.

!

CAUTION

▲

!

WARNING

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit to

OFF at disconnect switch(es).

Unit may have multiple power supplies.

APPLY

SILICONE CAULKING

ON TOP &

BOTH SIDES

OF AIR HOOD

AIR HOOD SHOWN IN THE OPEN POSITION