38

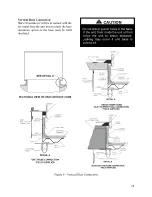

Draw-through cooling coils will have a

negative static pressure in the drain pan area.

This will cause an un-trapped drain to back

up due to air being pulled up through the

condensate drain piping.

Condensate drain trapping and piping must

conform to all applicable governing codes.

Draw-Through Coils

Figure 20 - Draw-Through Drain Trap

The X dimension on the draw-through trap

must be at least equal to the absolute value

of the negative static pressure in the drain

pan plus one inch. To calculate the static

pressure at the drain pan add the pressure

drops of all components upstream of the

drain pan, including the cooling coil, and

add the return duct static pressure. Include

the dirt allowance pressure drop for the

filters to account for the worst-case scenario.

The height from top of the bottom bend of

the trap to the bottom of the leaving pipe

must be at least equal to one half of the X

dimension. This ensures that enough water

is stored in the trap to prevent losing the

drain seal during unit startup

Note:

The absolute value of the fan inlet

pressure will always be greater than or equal

to the absolute value of the static pressure in

the drain pan on draw-through units, so the

fan inlet pressure is a safe value to use for

the drain pan static pressure.

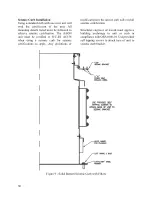

Table 7 - Draw-Through Drain Trap

Dimensions (Metric)

Table 8 - Draw-Through Drain Trap

Dimensions (Imperial)

Draw-Through

Drain Pan Pressure

Trap Dimensions

Negative Static

X

X/2

(inches of water)

(inch)

(inch)

-0.50

1.50

0.75

-1.00

2.00

1.00

-1.50

2.50

1.25

-2.00

3.00

1.50

-2.50

3.50

1.75

-3.00

4.00

2.00

-3.50

4.50

2.25

-4.00

5.00

2.50

Draw-Through

Drain Pan Pressure

Trap Dimensions

Negative Static

X

X/2

(mmHg)

(millimeters) (millimeters)

-0.93

38.1

19.1

-1.87

50.8

25.4

-2.80

63.5

31.8

-3.74

76.2

38.1

-4.67

88.9

44.5

-5.60

101.6

50.8

-6.54

114.3

57.2

-7.47

127

63.5

Unit must not be operated without a p-

trap. Failure to install a p-trap may

result in overflow of condensate water

into the unit.

CAUTION

Note: 1 mm = 0.1 cm

Summary of Contents for RQ NextGen Series

Page 2: ......

Page 26: ...26 Figure 3 RQ Cabinet Standard and Power Exhaust Gasket Locations...

Page 40: ...40 Figure 23 Post Corner Hole Piping Figure 24 Post Back Hole Piping...

Page 88: ...88 Gas Heater Operating Instructions Figure 36 Gas Heater Instructions...

Page 95: ...95...

Page 96: ...96...

Page 105: ...105 Maintenance Log E Coated Coil...

Page 107: ...107...