66

Glycol solution must be used if ambient

temperatures are expected to fall below

freezing or if the loop entering water

temperature to the unit is below 10°C (50°F)

while operating in the heating mode (heat

pump units only). Adding glycol to

condenser water causes an increase in

pressure drop and also results in a decrease in

unit performance. A minimum concentration

of 20% glycol solution is recommended.

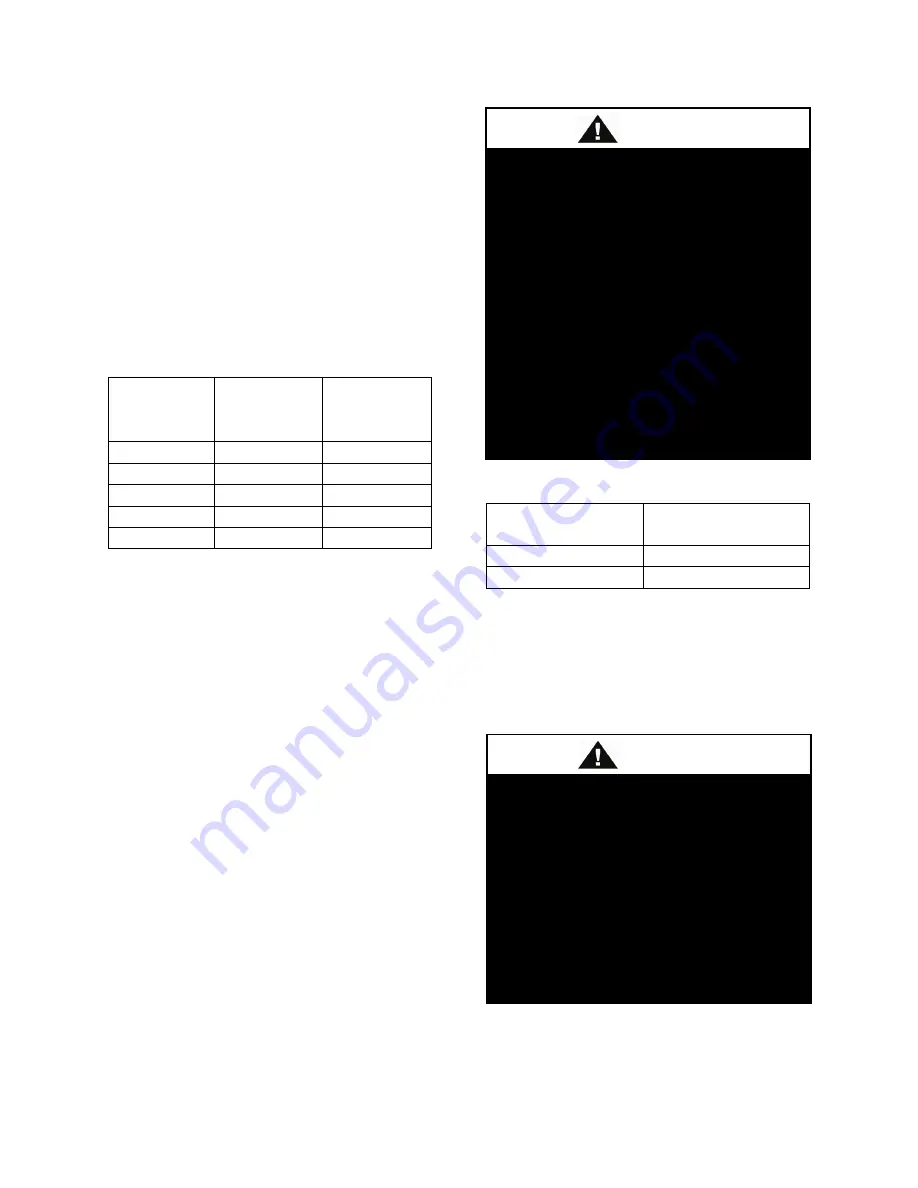

Table 23 - Glycol Concentration Freezing

Points

% Glycol

Ethylene

Glycol

[

°

C (

°

F)]

Propylene

Glycol

[

°

C (

°

F)]

0

0 (32)

0 (32)

20

-7.8 (18)

-7.2 (19)

30

-13.9 (7)

-12.8 (9)

40

-21.7 (-7)

-21.1 (-6)

50

-33.3 (-28)

-32.8 (-27)

Water loop piping that runs through unheated

areas or outside the building must be

insulated.

Never operate the unit in heat pump mode

with a saturated suction temperature below

1.7

°

C (35°F) for pure water systems or below

the freezing point +(-16.1

°

C [3°F]) of the

aqueous solution of water and glycol.

Water Piping

Verify that a water flow switch is installed

between the condenser water supply and

return connections. This sensor provides a

signal to the unit controller that water flow is

present in the refrigerant-to-water heat

exchanger and the unit can operate without

damaging unit components.

Table 24 - Condenser Water Connections

Model (RQ-)

Supply and Return

Connection Size

002

3/4” Sweat

003, 004, 005, 006

1” Sweat

Only use approved water pipe material.

Avoid using galvanized material for water

lines/fittings as the material is corrosive and

may cause fouling of the water system.

Condenser water pump must be field sized

and installed between the cooling

WATER PRESSURE

Prior to connection of condensing

water supply, verify water pressure is

less than maximum pressure shown

on unit nameplate. To prevent injury

or death due to instantaneous release

of high pressure water, relief valves

must be field supplied on water piping.

Supply water connection may require

a backflow preventer to prevent

supply makeup water from backing up

into the public water system.

WARNING

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts, in

a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

CAUTION

Note:

3/4” = 19mm, 1” = 25 mm

Summary of Contents for RQ NextGen Series

Page 2: ......

Page 26: ...26 Figure 3 RQ Cabinet Standard and Power Exhaust Gasket Locations...

Page 40: ...40 Figure 23 Post Corner Hole Piping Figure 24 Post Back Hole Piping...

Page 88: ...88 Gas Heater Operating Instructions Figure 36 Gas Heater Instructions...

Page 95: ...95...

Page 96: ...96...

Page 105: ...105 Maintenance Log E Coated Coil...

Page 107: ...107...