76

pulled out from the cabinet to view the air

seals. On larger units, the energy recovery

wheel may be accessible inside the walk-in

cabinet.

A business card or two pieces of paper can be

used as a feller gauge, (typically each .004”

thick) by placing it between the face of the

wheel and pile seal.

Using the paper, determine if a loose slip fit

exist between the pile seal and wheel when

the wheel is rotated by hand.

To adjust air seal clearance, loosen all seal

plate retaining screws holding the separate

seal retaining plates to the bearing support

channels and slide the seals plates away from

the wheel. Using the paper feeler gauge,

readjust and retighten one seal plate at a time

to provide slip fit clearance when the wheel

is rotated by hand.

Confirm that the wheel rotates freely. Apply

power to the unit and confirm rotation.

Visually inspect the belt and ensure the belt

is tracking near the center of the rim. Verify

the wheel speed is approximately 45-50

RPM. Confirm there is no excessive noise

such as scraping, brushing, or banging.

Polymer Wheel Installation

Energy recovery cassettes are incorporated

within

the design of packaged units,

packaged air handlers and energy recovery

ventilators. In each case, it is recommended

that

the

following

considerations

be

addressed:

Polymer Wheel Accessibility

The cassette and all its operative parts; i.e.:

motor, belt, pulley, bearings, seals and

energy transfer segments must be accessible

for service and maintenance. This design

requires that adequate clearance be provided

outside the enclosure. Where cassettes are

permanently installed in a cabinet, access to

both sides of the cassette must be provided.

Polymer Wheel Orientation & Support

The Energy Recovery Cassette may be

mounted in any orientation. However, Care

must be taken to make certain that the

cassette frame remains flat and the bearing

beams are not racked.

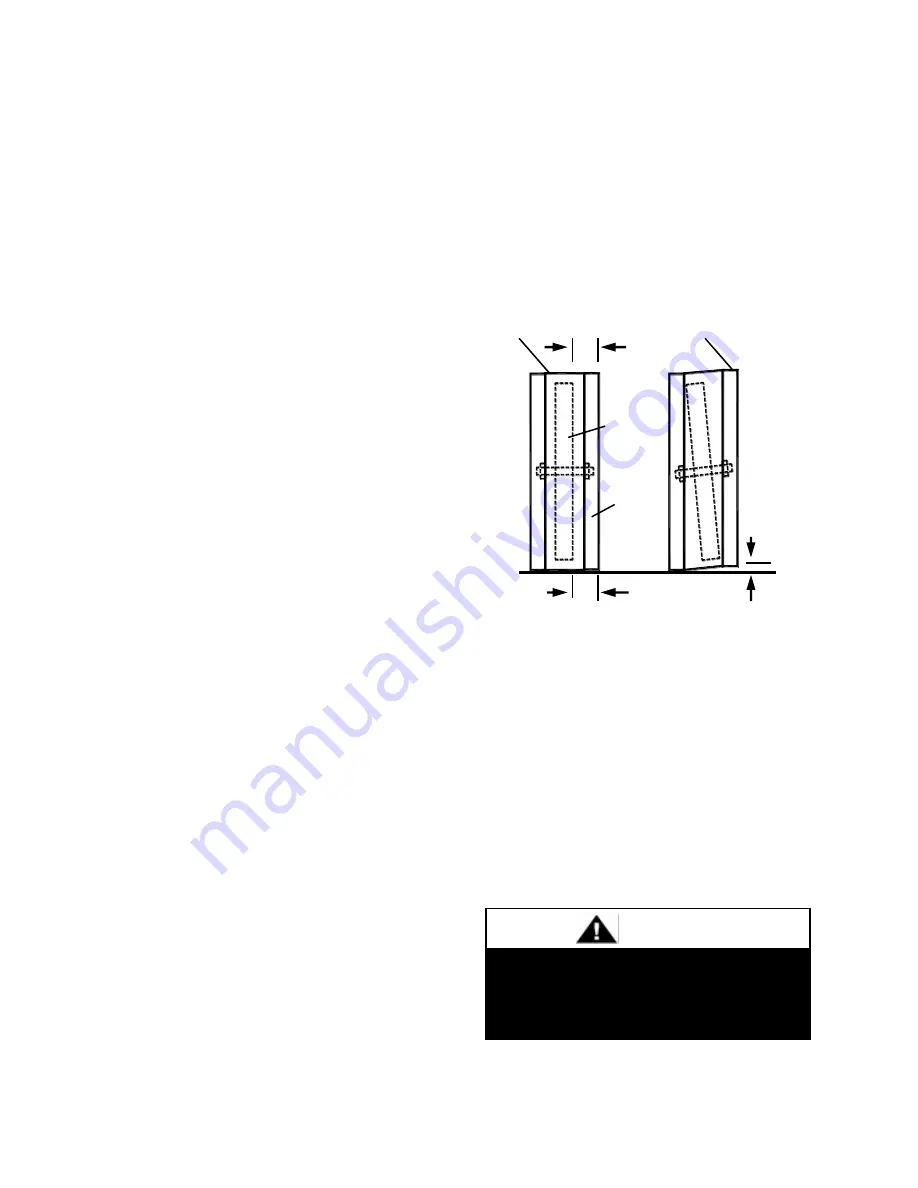

Avoid Racking of Cassette Frame

To verify, make certain that the distance

between wheel rim and bearing beam is the

same at each end of the bearing beam, to

within 1/4 of an inch (dimension A & B).

This amount of racking can be compensated

for by adjusting the diameter seals.

If greater than 1/4 inch (dimension C),

racking must be corrected to ensure that drive

belt will not disengage from wheel.

Polymer Wheel Startup Procedure

B

C

A

Bearing beams shown

racked

Frame

Wheel

Bearing

beams

(2)

Flat surf ace

Keep hands away from rotating wheel!

Contact with rotating wheel can cause

physical injury.

CAUTION

Summary of Contents for RZ Series

Page 2: ......

Page 31: ...31 Figure 4 4 Point Lift RZ Series Air Cooled Condenser Unit ...

Page 90: ...90 Gas Heater Operating Instructions ...

Page 108: ...108 Maintenance Log E Coated Coil ...

Page 110: ...110 ...

Page 111: ......