77

1.

By hand, turn wheel clockwise (as

viewed from the pulley side), to verify

wheel turns freely through 360º rotation.

2.

Before applying power to drive motor,

confirm wheel segments are fully

engaged in wheel frame and segment

retainers are completely fastened. (See

Segment Installation Diagram).

3.

With hands and objects away from

moving parts, activate unit and confirm

wheel rotation. Wheel rotates clockwise

(as viewed from the pulley side).

4.

If wheel has difficulty starting, turn

power off and inspect for excessive

interference between the wheel surface

and each of the four (4) diameter seals.

To correct, loosen

diameter

seal

adjusting screws and back adjustable

diameter seals away from surface of

wheel, apply power to confirm wheel is

free to rotate, then re-adjust and tighten

hub and diameter seals, as shown in hub

seal adjustment diagram.

5.

Start and stop wheel several times to

confirm seal adjustment and to confirm

belt is tracking properly on wheel rim

(approximately 1/4” from outer edge of

rim).

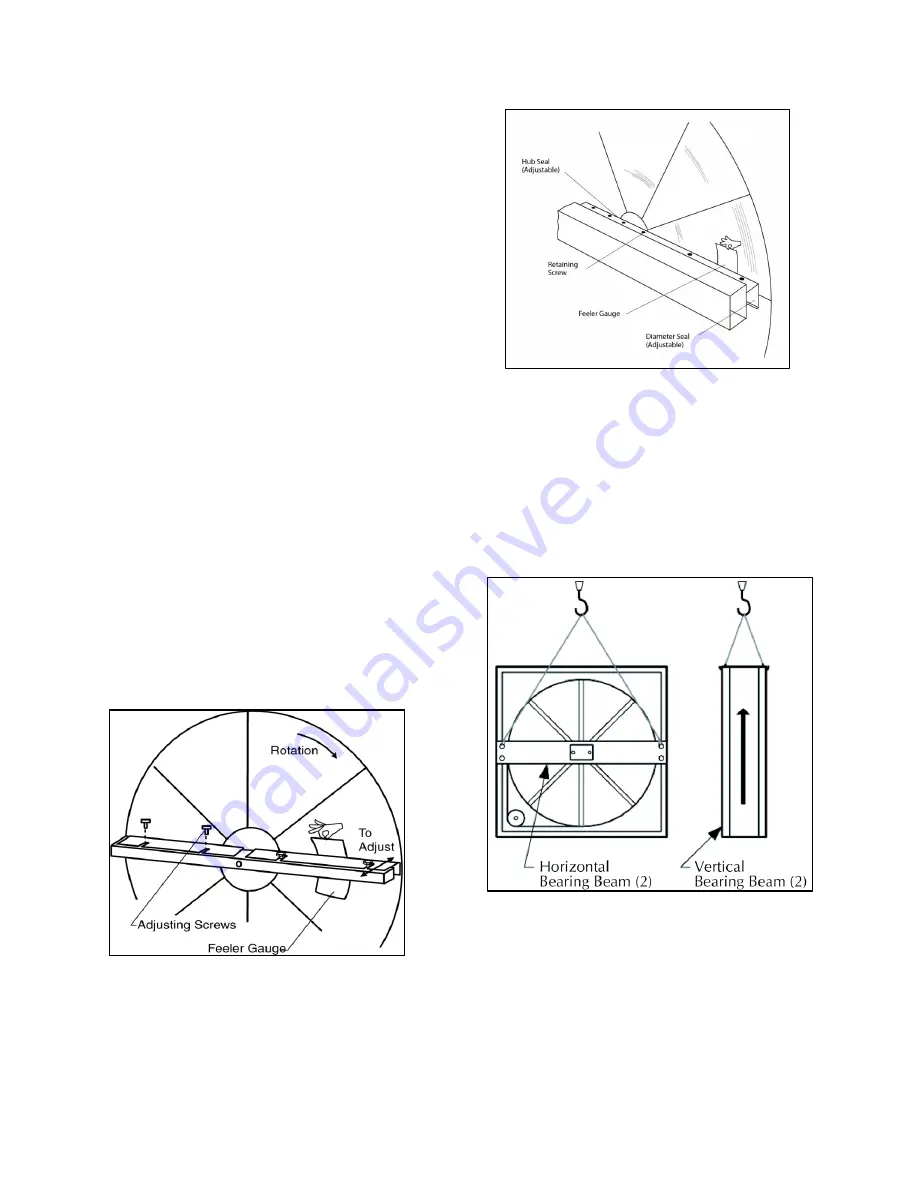

Diameter Seal Adjustment

Hub Seal Adjustment

Polymer Wheel Routine Maintenance and

Handling

Handle cassettes with care. Lift all cassettes

by the bearing support beam. Holes are

provided on both sides of the bearing support

beams to facilitate rigging as shown in the

following illustration.

Lifting Hole Locations

Routine maintenance of the Energy Recovery

Cassettes includes periodic cleaning of the

Energy Recovery Wheel as well as inspection

of the Air Seals and Wheel Drive

Components as follows:

Summary of Contents for RZ Series

Page 2: ......

Page 31: ...31 Figure 4 4 Point Lift RZ Series Air Cooled Condenser Unit ...

Page 90: ...90 Gas Heater Operating Instructions ...

Page 108: ...108 Maintenance Log E Coated Coil ...

Page 110: ...110 ...

Page 111: ......