44

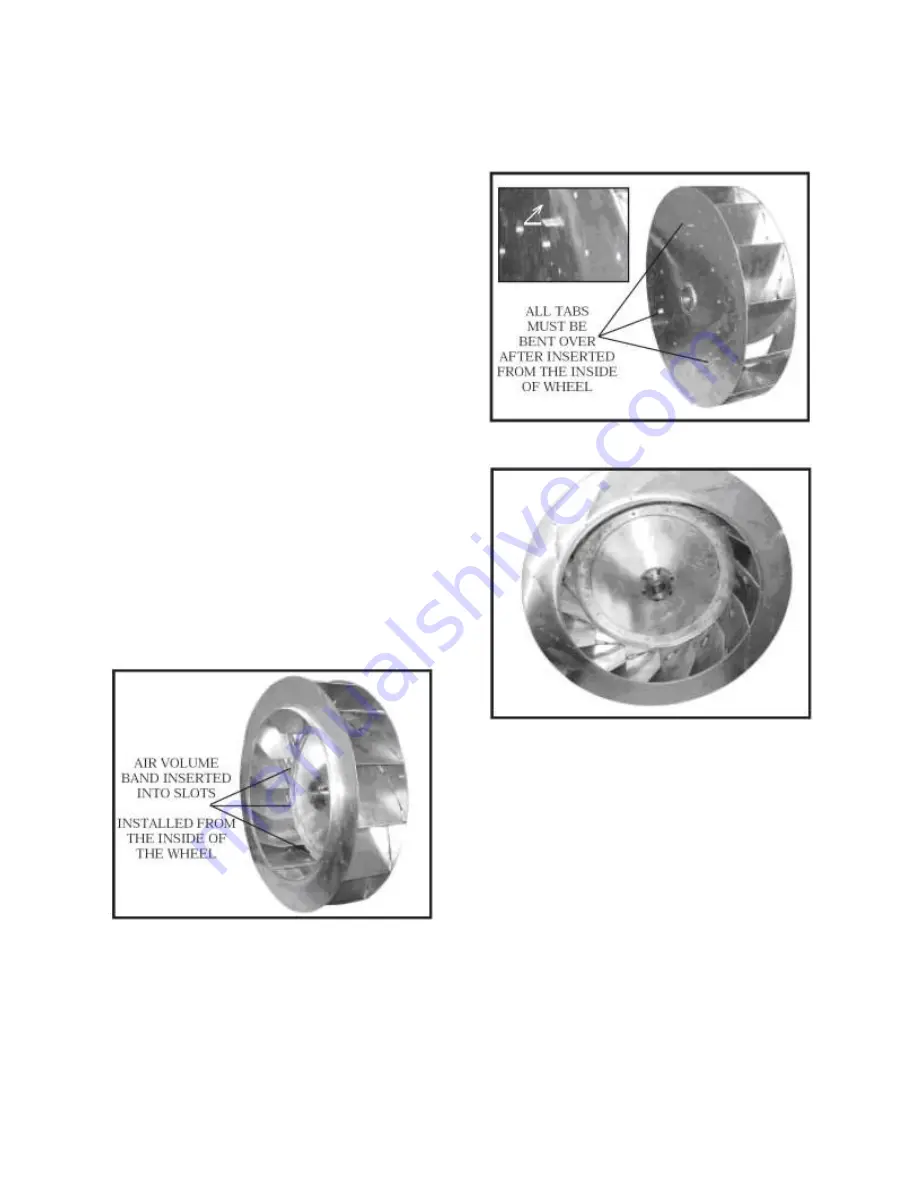

required, the band can be removed from the

wheel.

Use fan program in AAONEcat32 to

determine the new band size for the required

cfm and static pressure.

The following photos of a wheel are

provided for practical guidelines only in

order to identify the air band location in the

wheel. Actual field installation of the air

band into the wheel will require access into

and through the blower wheel venture,

which may require removal of the blower

motor and wheel.

Air volume bands are made of aluminum,

sized and equipped with easy bend tabs that

are to be inserted into pre-punched slots

provided on the wheel. Once the band has

been inserted into the slots, it MUST BE

secured by bending the tabs over from the

back side of the wheel and also MUST BE

secured from the inside by connecting the

ends together with a pop-rivet in the holes

provided on the ends of the band.

Figure 20 - Blower Wheel with Band

If the band is field installed, a hand held

pop-rivet

tool

is

recommended

for

connecting the band ends together. Caution

must be taken to assure that the band is

tightly installed and no damage, denting or

alteration to the wheel or blades occurs

during the installation.

Figure 21 - Band Tabs

Figure 22 - Blower Wheel

Summary of Contents for SA-028

Page 2: ......

Page 20: ...20 Figure 2 One Piece Single Unit Lifting Details...

Page 21: ...21 Figure 3 Two Piece Single Unit Coil Section Lifting Details...

Page 22: ...22 Figure 4 Two Piece Single Unit Fan Section Lifting Details...

Page 23: ...23 Figure 5 One Piece Dual Unit Lifting Details...

Page 24: ...24 Figure 6 Two Piece Dual Unit Coil Section Lifting Details...

Page 25: ...25 Figure 7 Two Piece Dual Unit Fan Section Lifting Details...

Page 28: ...28 Figure 10 Dual unit with splices after being bolted together...

Page 63: ...63...