12

/

13

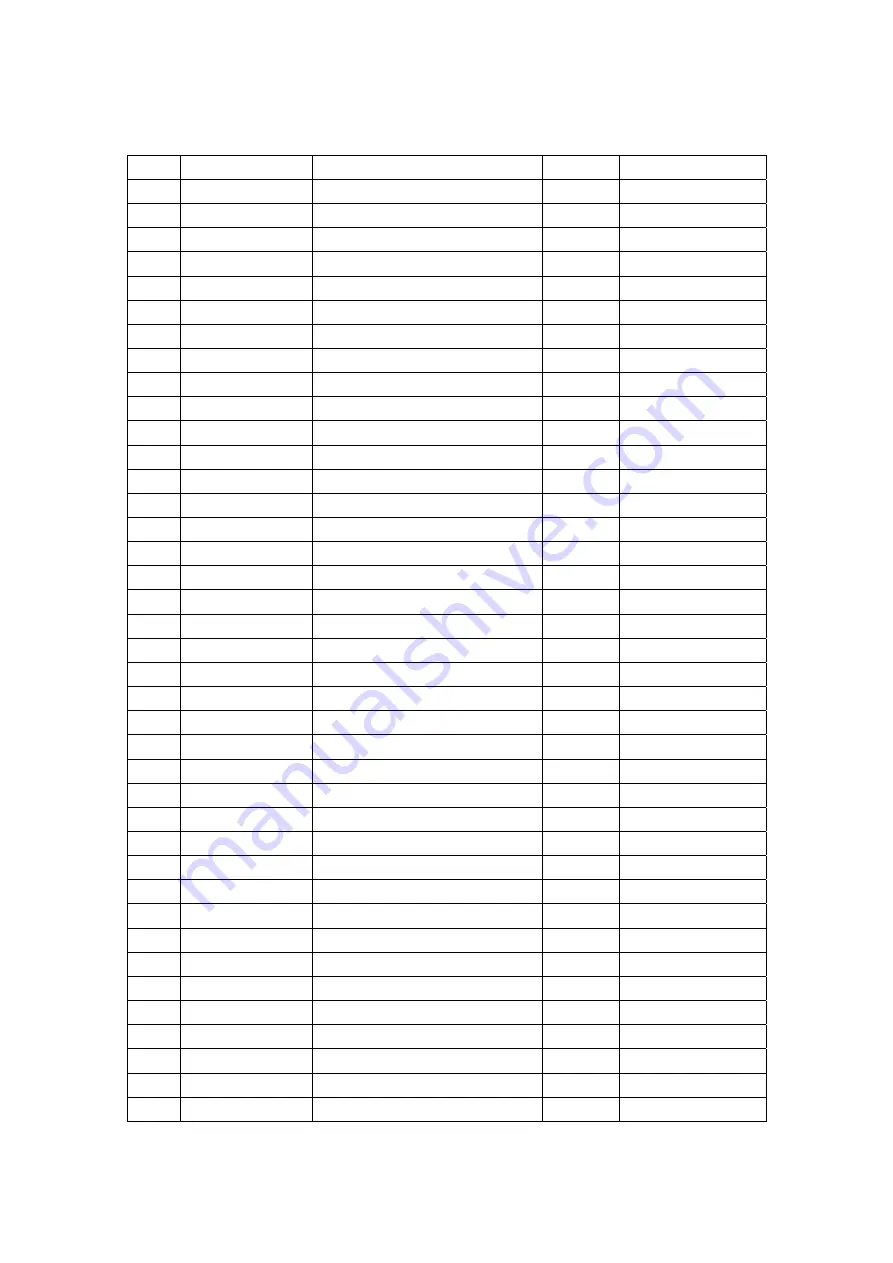

PARTS CODE LIST

ITEM CODE

DESCRIPTION

QTY

NOTE

1 ES04-00010-000

Handle

sleeve

3

2

5206-00016-000

Hex nylon locknut

3

3 5302-00016-000

Flat

washer

2

φ

16

4 SL01-05000-000

column

cover

1

5 SL01-01000-000

Column

1

6 5302-00006-000

Flat

washer

18

φ

6

7 5104-06012-000

Hex

bolt

8

M6*12

8 SL01-00002-000

block

wheel

2

9 SL01-00001-000

long

bolt

2

10 SL01-00022-000

Bush

1

11 SL01-00007-000

Hex

bolt

1

M16*195

12 SL01-00014-000

Oil

pipe

1

13 SL01-00015-000

Extension

connector

1

14

QY030S-00

Air-Hydraulic Foot Pump

1

15 SL01-00008-000

lock

bar

1

16 SJ01-00033-000

β

pin

1

17 5202-00016-000

Hex

nut

2

M16

18 SL01-02000-000

Chain

basement

1

19 SL01-00020-000

Protective

brush

2

20

5110-06008-000

Cross recess head screw

16

M6*8

21

5304-00025-000

Circlip for shaft

2

φ

25

22 SL01-00006-000

Wheel

axle

1

23

SL01-12002-000

Oil less bearing

1

24 SL01-12001-000

roller

1

25

5109-06010-000

socket screws with flat point

1

M6*10

26 SL01-00004-000

Roller

seat

1

27 SL01-00017-000

Protective

housing

1

28 SL01-11001-000

Roller(

Ⅲ)

2

29

SL01-11002-000

Oil less bearing

2

30

5304-00020-000

Circlip for shaft

8

φ

20

31 5104-12040-000

Hex

bolt

6

M12*40

32 5306-00012-000

Spring

washer

6

φ

12

33 5302-00012-000

Flat

washer

6

φ

12

34 5102-08020-000

Hex

bolt

8

M8*20

35 5302-00008-000

Flat

washer

16

φ

8

36 SL01-00012-000

swivel

Caster

2

37

5206

‐

00008

‐

000

Hex nylon locknut

8

M8

38

5304

‐

00016

‐

000

Circlip for shaft

4

φ

16

39

SL01

‐

00011

‐

000

Wheel axle

2

Summary of Contents for AutoLift AL-182093

Page 4: ...7 13 Fig 3 Fig 5 Fig 4 Fig 6 Now the hoist is ready for use ...

Page 7: ...10 13 PARTS DRAWING ...

Page 8: ...11 13 ...