FITTING THE FLUE OUTLET AND

HOT PLATE

The flue outlet spigot is found packed inside the

appliance . The hot plate (blanking plate) is sup-

plied fitted to the top opening and is removed by

turning clockwise (as is the flue outlet).

Smear a very thin layer of fire cement on the

mateing faces of the flue outlet and the hot plate.

Fit the outlet to the appliance in the desired

position.

Lock into place by rotating anti-clockwise and

tighten by tapping with a block of wood and mallet

from inside of the appliance. Similarly, fit the hot

plate (blanking plate) to the unused opening. Clean

off any surplus fire cement.

Place appliance on the hearth and make sure that

it is level and does not rock.

Connect the chimney ensuring all joints are sealed

with fire cement.

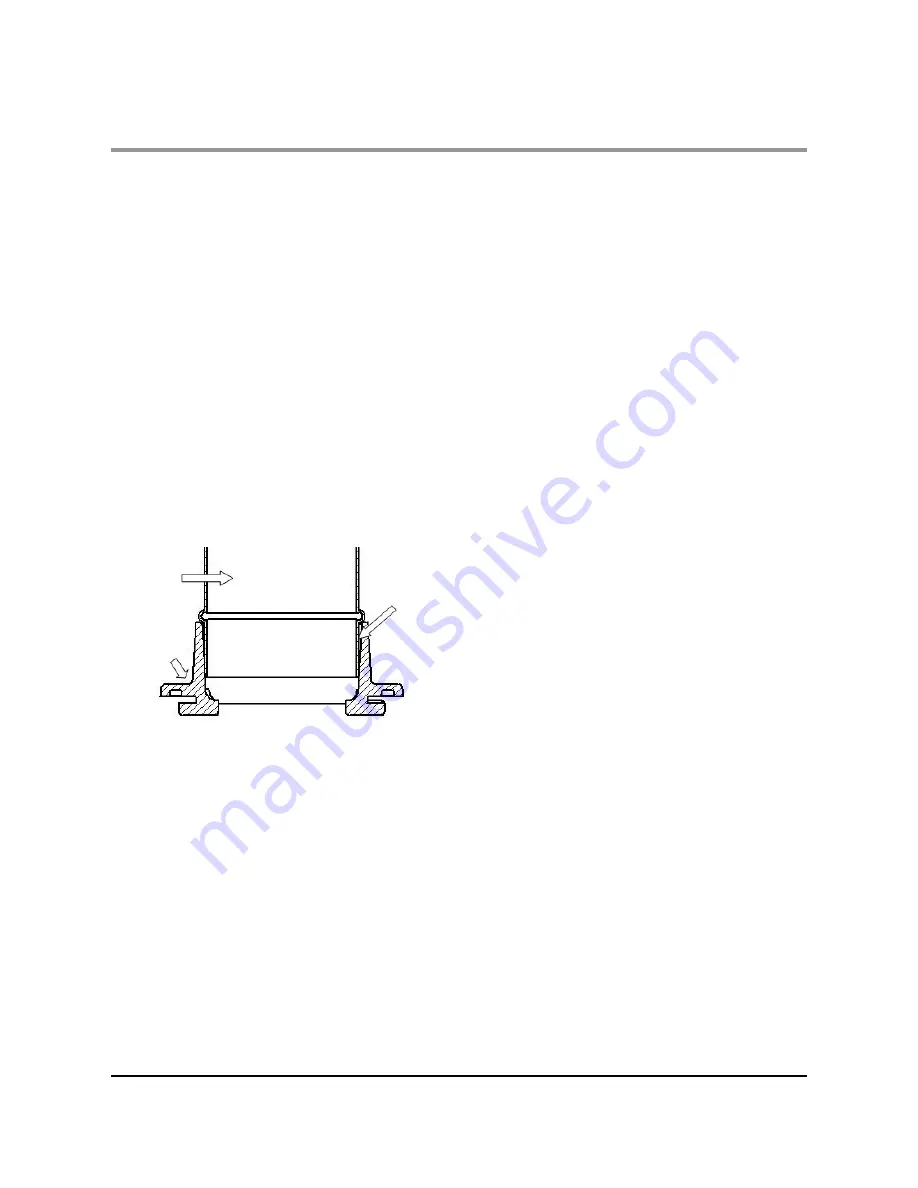

Note : The flue pipe must be fitted inside the outlet

spigot. Failure to do so could result in the spillage

of condensation running down the flue.

( See Fig. 1 )

SEALING OF TERMINALS

If an add in boiler is not to be fitted,

please en-

sure that the two partially cut circular terminals

(located on the rear of the appliance) are sealed

with fire cement, and thus preventing surplus air

entering the firebox, resulting in less efficiency and

poor fuel consumption.

FLUES AND CHIMNEYS

The flue draw is critical on any installation and

should be checked to ensure that it matches what

is specified. If it is higher than recommended,

provision must be made to correct the over draw.

The draw can vary in different weather conditions

and the customer should be made aware of this.

Failure to correct an over-drawing flue will

invalidate the warranty.

Please remember that chimney draught is

dependent on four main factors :

Flue gas temperature

Flue height

Flue size

Flue terminal

The stove must be connected to a suitable and

efficient flue so that products of combustion

(fumes) from the stove are expelled to the outside

air. To ensure a good up draught it is important

that the flue gases are kept warm and that the flue

size suits the stove. The termination of the outlet at

the top of the flue also needs to comply with

Building

Regulations. The minimum effective height of the

flue must be at least 4.5 metres from the top of the

stove to the top of the flue outlet. When warm the

flue draught should be between 0.1 to 0.2 mb.

A chimney may comply with regulations but could

still be subject to down draught and similar

problems. A chimney terminating above the ridge

level is generally less likely to suffer such

problems.

If a new chimney is being provided it should fully

comply with the relevant Building Regulations that

specify the requirements for solid fuel burning

installations. Suitable types of chimney include the

following :

Masonry Chimney :

Built with clay or concrete

liners, or a chimney block system meeting Building

Regulations. These types of chimney should be

installed in accordance with the Building

Regulations and BS 6461:Part 1.

Factory Made Insulated Chimney :

Complying

with BS 4543:Part 2 (often called “Class 1

prefabricated metal chimney”). These types of

chimney should be installed in accordance with

Building Regulations and BS 7566: Parts 1 to 4.

Aarrow Ecoburn Stoves

10

INSTALLATION

Fig. 1. Flue & Spigot Fitting

Inside

Flue

Pipe

Outer

Spigot