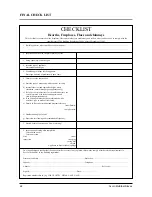

MULTIFUEL GRATE

GRATE

The grates in the Acorn Multifuel units comprise a

series of reciprocating cast iron bars seated on a

pivoted "comb". All bars in the grate are identical,

but every other bar is turned through 180 degrees,

with the ends of the bars marked "H" sitting on the

high sections of the comb, and the ends marked "L"

sitting on the low sections.

ASSEMBLING THE GRATE

To assemble the grate, fit bars to low sections of the

comb first, inserting end marked "H" into rear

channel with groove on underside of bar located on

upstand tab, and then lowering end marked "L"

onto the low section of the comb. The upper bar is

fitted in a similar manner, but with the end marked

"L" inserted in the rear channel, and the end

marked "H" seated on the high section of the comb.

10

Acorn Multifuel Stoves

INSTALLATION

GRATE BAR REPLACEMENT

After extended use it may be necessary to

replace some of the grate bars.

Periodic inspection of the bars is recommended

and the removal of any nails or wire that may be

present after burning wood. All the grate bars in

each appliance are identical and can easily be

lifted out after removal of the fuel retainers.

Remove damaged grate bars and replace with

casting of the same type, fitting as per

instructions above. (Check Identification letters

on the casting when reordering).