30

6. If re-using the spark plug, use a wire

brush to clean any dirt from around the

spark plug base then re-gap the spark

plug.

7. Screw the spark plug back into the

spark plug hole using the spark plug

wrench. Do not over-tighten spark plug.

Recommended tightening of spark plug

is 1/2 to 3/4 of a turn after spark plug

gasket contacts spark plug hole.

Spark Plug Torque: 17.5 N*m

(1.75kgf*m, 13 lbf*ft)

NOTE:

If a torque wrench is not

available when installing a spark plug, a

good estimate of the correct torque is

1/4-1/2 turn past finger tight. However,

the spark plug should be tightened to the

specified torque as soon as possible.

8. Reinstall the spark plug boot and spark

plug cover.

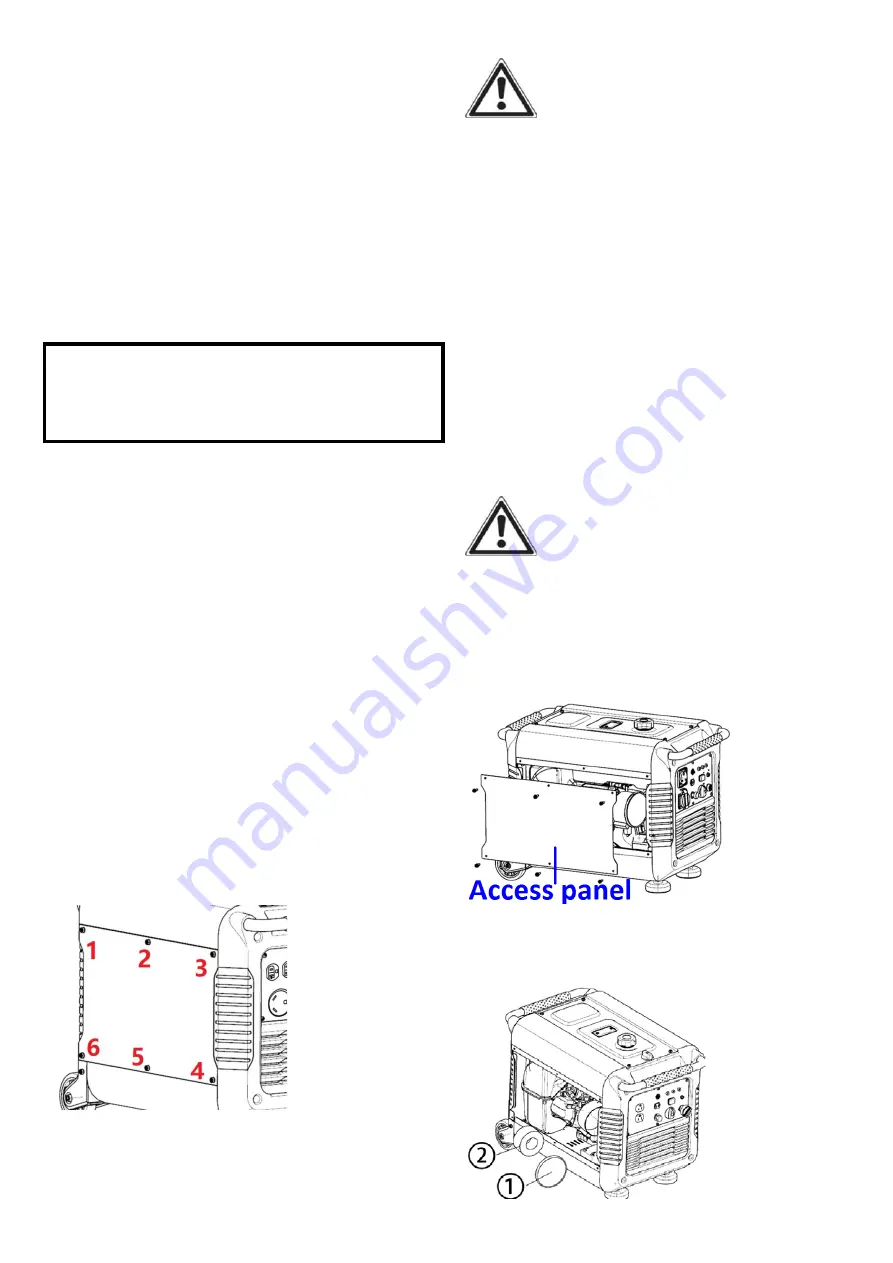

9. Reinstall the access panel and tighten

the bolts.

1) put the screw #1 & 4 in the access

panel, but donot tighten it fully.

2) put the screw #3 & 6 in the access

panel, but donot tighten it fully.

3) put the screw #2 & 5 in the access

panel, but donot tighten it fully.

4) tighten all screws well

CARBURETOR ADJUSTMENT

WARNING

The carburetor is a vital part of the

engine. Adjusting should be left to our

company authorized dealer with the

professional knowledge, specialized date,

and equipment to do so properly.

AIR FILTER

Routine maintenance of the air cleaner

helps maintain proper airflow to the

carburetor. Occasionally check that the

air cleaner is free of excessive dirt. Refer

to Recommended Maintenance Schedule

above.

CAUTION:

running the engine

with dirty, damaged or missing air

cleaner element will cause the engine to

wear out prematurely.

1.

Loosen the screws, and remove the

access panel.

2.

Remove the clip holding the air filter

cover①. Take out the air filter cover and

foam element②.

Summary of Contents for A112003

Page 37: ...37 WIRING DIAGRAM...