Chapter 11

Troubleshooting

11-7

Table 11.B

Fault Descriptions and Diagnostics (Continued)

Potential Cause

Fault Description

Fault/Message

Overvoltage

“bus overvoltage”

(Bit 8)

The power bus voltage has exceeded 405V DC.

1. Power Driver Board is malfunctioning and incorrectly sensing the bus

voltage.

2. A vertical axis with insufficient counterbalancing is overdriving the

servomotor and causing excessive energy to be returned to the power

supply bus.

3. The system inertia is too high causing excessive energy to be returned to

the power supply bus.

4. Input line voltage exceeds the maximum drive input voltage rating.

5. The position controller acceleration / deceleration rate is incorrectly set.

6. The shunt regulator or transistor has malfunctioned.

7. Shunt regulator fuse has blown.

8. Shunt regulator resistor not connected to drive.

The DC Power Bus is continuously

monitored. If it exceeds a preset level

a fault is sensed and the power

supply is disabled.

Component on Logic Control Board has malfunctioned – replace Logic Control

Board.

Component malfunction of input

A/D converter.

External A/D

Conversion Fault

“ext A/D fault”

(Bit 10)

Internal A/D

Conversion Fault

“int A/D fault”

(Bit 11)

Component on Logic Control Board has malfunctioned – replace Logic Control

Board.

Component malfunction of input

A/D converter.

Problem reading or writing to

EEprom.

EEPROM Fault

“EEprom fault”

(Bit 14)

1. Re-initialize EEprom (parameter 128).

2. Malfunctioning EEprom – replace Memory Board.

Auto Tune Fault

“auto tune flt”

(Bit 15)

Auto tune cycle time has

exceeded 2 seconds.

1. Auto tune current limit should be increased to speed up the auto tune cycle.

2. Auto tune velocity should be decreased to speed up auto tune cycle.

3. Motor is disconnected or not able to turn.

4. Motor power/resolver continuity disconnected or miswired.

1. Enable not applied.

Enable has not been applied

within 60 seconds during auto

tune,

Summary of Contents for 1391-DES Series

Page 2: ...User Manual 1391 DES Digital AC Servo Drive ...

Page 10: ...Chapter 1 Introduction 1 10 End of Chapter ...

Page 38: ...Chapter 5 Inputs Outputs and Switch Settings 5 8 End of Chapter ...

Page 85: ...Chapter 8 Start Up 8 16 End of Chapter ...

Page 89: ...Chapter 9 1326 AC Servomotors 9 4 End of Chapter ...

Page 107: ...Chapter 11 Troubleshooting 11 12 End of Chapter ...

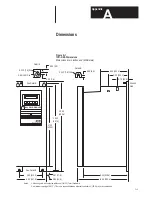

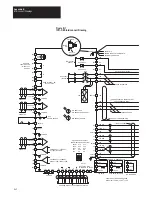

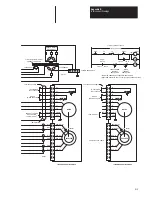

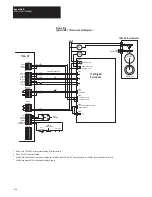

Page 123: ...Appendix B Interconnect Drawings B 12 End of Appendix ...

Page 127: ...Appendix C Cable Information C 4 End of Appendix ...

Page 135: ...Appendix E Parameter Record E 8 End of Appendix ...

Page 136: ...Notes ...

Page 137: ...Notes ...

Page 138: ...Notes ...

Page 139: ...Notes ...

Page 140: ...Notes ...

Page 141: ...Notes ...

Page 142: ...Notes ...

Page 143: ...Notes ...

Page 144: ...Notes ...

Page 145: ...Notes ...

Page 148: ...IMC is a trademark of Allen Bradley Company Inc ...