18

G

B

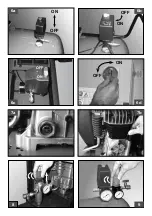

pressure can be regulated in order to optimize use of air-powered tools

operating on the knob with the valve open (pulling it up and turning it in a

clockwise direction to increase pressure and counterclockwise to reduce

this) (

fig. 8

). Once you have set the value required, push the knob down to

lock it.

• The value set can be checked on the gauge (for versions equipped with

this,

fig. 9

).

•

Please check that the air consumption and the maximum working

pressure of the pneumatic tool to be used are compatible with the

pressure set on the pressure regulator and with the amount of air

supplied by the compressor

.

• When you have finished working, stop the machine, pull out the plug and

empty the reservoir.

AIR RECEIVER (ON TANk-MOUNTED UNITS)

3

• Corrosion must be prevented: depending on the conditions of use,

condensate may accumulate inside the tank and must be drained every

day. This may be done manually, by opening the drain valve, or by means

of the automatic drain, if fitted to the tank. Nevertheless, a weekly check of

correct functioning of the automatic valve is needed. This has to be done

by opening the manual drain valve and check for condensate (

fig. 13

).

• Periodical service inspection of the air receiver is needed, as internal

corrosion can reduce the steel wall thickness with the consequent risk

of bursting. Local rules need to be respected, if applicable. The use of

the air receiver is forbidden once the wall thickness reaches the minimum

value as indicated in the service manual of the air receiver (part of the

documentation delivered with the unit).

• Lifetime of the air receiver mainly depends on the working environment.

Avoid installing the compressor in a dirty and corrosive environment, as

this can reduce the vessel lifetime dramatically.

• Do not anchor the vessel or attached components directly to the ground

or fixed structures. Fit the pressure vessel with vibration dampers to avoid

possible fatigue failure caused by vibration of the vessel during use.

• Use the vessel within the pressure and temperature limits stated on the

nameplate and the testing report.

• No alterations must be made to this vessel by welding, drilling or other

mechanical methods.

MAINTENANCE

4

• The service life of the machine depends on maintenance quality.

•

PRIOR TO ANy OPERATION SET THE PRESSURE SWITCH TO THE

OFF POSITION, PULL OUT THE PLUG AND COMPLETELy DRAIN THE

RESERVOIR.

• Check that all screws (in particular those of the head of the unit) are

tightly drawn up (

fig. 10

). The check must be carried out prior to the first

compressor starting.

TABLE 1 – TIGHTENING OF HEAD TENSION RODS

Nm

Min. torque

Nm

Max. torque

Screw M6

9

11

Screw M8

22

27

Screw M10

45

55

Screw M12

76

93

Screw M14

121

148

• Clean the suction filter according to the type of environment and in any

case at least every 100 hours. If necessary, replace the filter (a clogged

filter impairs efficiency while an inefficient filter causes harsher wear on the

compressor

(figures 11a - 11b)

.

• Change the oil after the first 100 hours of operation and subsequently

every 300 hours. Check the oil level periodically.

• Use

API CC/SC SAE 40

. (For cold climates,

API CC/SC SAE 20

is

recommended). Never mix different grade oils. If the oil changes color

(whitish = presence of water; dark = overheated), it is good practice to

replace the oil immediately.

• After topping up, tighten the plug (

fig. 12

) making sure that there are no

leaks during use. Once a week, check the oil level to assure lubrication in

time (

fig. 7a

).

• Periodically, check the tension of the belts which must have a flexion (f) of

around 1 cm (

fig. 14

).

*

Spent oil and condensate

MUST BE DISPOSED OF

in compliance with

protection of the environment and current legislation.

The compressor must be disposed in conformity with the methods

provided for by local regulations

POSSIbLE FAULTS AND RELATED PERMITTED REMEDIES

5

Request the assistance of a qualified electrician for operations on electric components (cables, motor, pressure switch, electric panel, etc).

TABLE 2 – MAINTENANCE

FUNCTION

AFTER THE

FIRST 100

HOURS

EVERy 100

HOURS

EVERy 300

HOURS

Cleaning of intake filter and/

or substitution of filtering

element

●

Change of oil*

●

●

Tightening of head tension

rods

The check must be carried out prior to the first

compressor starting.

Draining tank condensate

Daily

Checking the tension of

the belts

Periodically

FAULT

CAUSE

REMEDy

Air leak from the valve of the pressure switch.

Check valve does not perform its function

correctly due to wear or dirt on the seal.

Unscrew the hex-shaped head of the check

valve, clean the housing and the special rubber

disk (replace if worn). Re-assembler and tighten

carefully (

igures 15a-15b

).

Condensate drainage cock open.

Close the Condensate drainage cock.

Rilsan hose not inserted correctly in pressure

switch.

Insert the Rilsan hose correctly inside the

pressure switch

(ig. 16)

.

Reduction of eficiency, frequent start-up. Low

pressure values.

Excessively high consumption.

Decrease the demand of compressed air.

Leaks from joints and/or pipes.

Change gaskets.

Clogging of the suction ilter.

Clean/replace the suction ilter

(

igures 11a-11b

).

Slipping of the belt.

Check belt tension

(ig. 14).

Summary of Contents for A39B/150 CM3

Page 3: ......

Page 5: ......

Page 6: ...2 4 3c 3a 3b 1b 5 1a...

Page 7: ...6c 7b 7a 6a ON OFF OFF ON 6b OFF ON 6d 8 9 OFF ON...

Page 8: ...11b 15a 14 12 10 13 11a 15b...

Page 9: ...17b 16 18 17a 17c...

Page 47: ...46 G R 15a 15b rilsan rilsan 16 11a 11b 14 17a 17b 17c 1a 2 1b 3c 6d 1a 1b 18 5...

Page 68: ...67 R U S 15a 15b 16 11a 11b 14 17a 17b 17c 1a 2 1b 3c 6b 1a 1b 18 5...

Page 80: ...79 B G C C 11a 11b 14 17a 17b 17c 1a 2 1b 3c 6d 1a 1b 18...

Page 93: ...92 Single phase Three phase Three phase...

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ...2236111771 00...