P. 36 - Chap. 7 Start-up and operation

G

B

Customization operating parameter

Programming of compressor operation on a daily or weekly basis

Programming and signalling of the Manufacturer’s maintenance schedule

Machine self-protection system to signal fault pre-alarms and automatically stop the machine in the

event of serious problems

Remote machine control

Possibility of connecting the compressor via CAN-BUS interface (optional) to other similar compressors

for integrated management of the set of machines

Remote compressor monitoring via personal computer and dedicated software (optional)

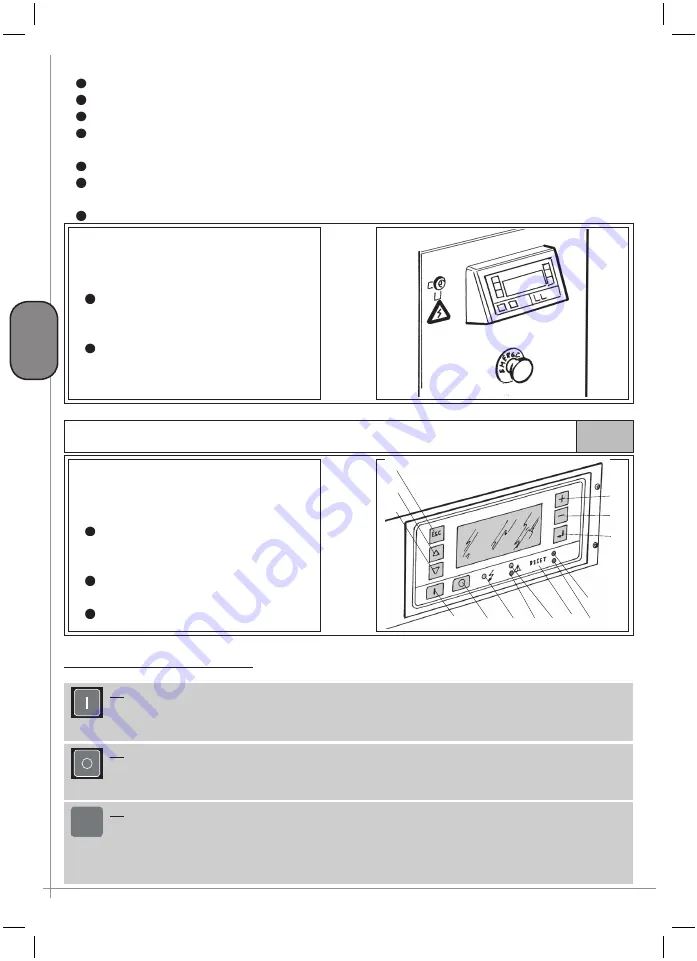

Fig. 34

The panel has two sections:

Control unit “mc

2

” of the

compressor

Emergency stop button

7.2.1

Control unit “mc

2

“

Fig. 35

The

front panel of the control unit “mc

2

”

comprises:

compressor programming and

control keyboard

Indicator / setting LEDs

back-lit LCD display

K4

K5

K3

K6

K1

K2

K7

K8

K9

L1

L2

L3

L4

L5

Control and programming keyboard

K1

START button (starting the compressor)

Used to start the machine. If remote control or programming (daily/weekly) are enabled, this key is used to enable

compressor functioning (priority control from keyboard). If alarm conditions have occurred, pressing of this key

has no effect

K2

STOP button (stop the compressor)

Permits timed stopping of the machine. If remote control or programming (daily/weekly) have been enabled, this

key can be used to disable compressor functioning (priority control). It does not operate at emergency level

K3

RESET button

Makes it possible to reset compressor fault messages after eliminating the causes of these. As the faults can be

displayed only in the main screen page, the RESET key is effective only during display of this.

During parameter modification operations, the RESET key can be used to restore the preset factory (default)

value for the type of compressor selected

RESET

Summary of Contents for FORMULA Series

Page 1: ...GENESIS FORMULA MODULO 5 5 15 kW USE AND MAINTENANCE HANDBOOK GB ...

Page 2: ......

Page 82: ...P 80 Chap 12 Diagrams G B 12 Diagrams Hydraulic pneumatic plant diagram 12 1 ...

Page 85: ...P 83 Chap 12 Diagrams G B Power circuit wiring diagram 5 5 15 kW Machines with air dryer 12 3 ...

Page 86: ...P 84 Chap 12 Diagrams G B Power circuit wiring diagram 11 kW Machines with inverter 12 4 ...

Page 89: ...P 87 Chap 12 Diagrams G B Auxiliary circuit wiring diagram 11 kW Machines with inverter 12 7 ...