P. 41 - Chap. 7 Start-up and operation

G

B

The emergency stop button is intercepted by the

monitoring unit which displays the following message

with LED L3 on

To reset,

release the EMERGENCY STOP button lock

and press button K3-RESET

12

EMERGENCY STOP

compress.-Block

RESET

7.4

Parameter configuration - menu tree

The machine was configured at the plant during testing;

the end user, however, can change some operating

parameters to customize machine performance to the specific applications.

Other parameter changes cannot be made Customer but only by Authorized Service Centre skilled

personnel.

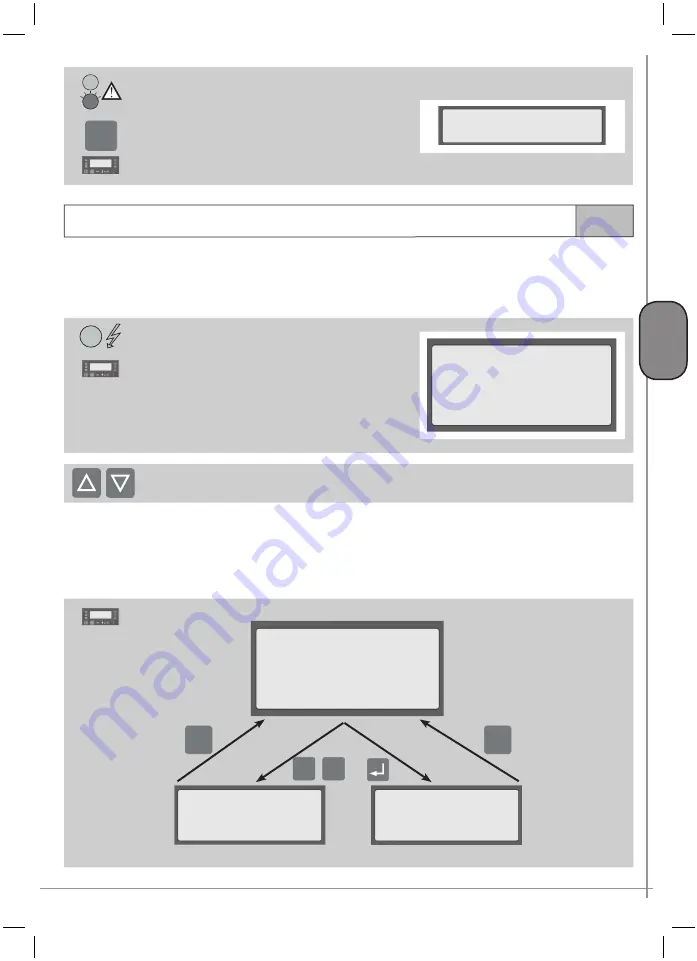

The main screen page is displayed as follows:

LINE 1

net pressure

LINE 2

compression temperature of air-oil mixture

LINE 3

messages about operating conditions

LINE 4

hour and date, informations menu access,

tree menu access, quick language change

message

13

Pressure XX.X bar

Temperature XXX °C

Ready for start

10:40 DOM 25/05/2003

To change the language, use the

K5

and

K6 keys

After 60 seconds from pressing of the last key, the display is set to a

low level of brightness

.

The first time a key is pressed (excluding the K1-START, K2-STOP, K3-RESET control keys),

high level

brightness

of the display is restored while subsequent pressing of the keys produces the associated

function.

14

ESC

ESC

+ -

ADDIZIONAL

INFORMATIONS

MENU

TREE

7.4.1

7.4.2

Pressure XX.X bar

Temperature XXX °C

Ready for start

10:40 DOM 25/05/2003

b

) to

MENU TREE

using the K9 (ENTER) key

This menu permits access to all compressor

control and programming functions; the

main screen page is redisplayed using

the

K4-ESC

key or automatically after

60 seconds

a

) to

ADDIZIONAL INFORMATIONS

using the K7 (PLUS) and K8 (MINUS)

keys

This menu permits fast access to significant

information without having to enter the

menu tree; the main screen page is

redisplayed using the

K4-ESC

key or

automatically after 60 seconds

From the main screen page, it is possible to access:

14

Summary of Contents for FORMULA Series

Page 1: ...GENESIS FORMULA MODULO 5 5 15 kW USE AND MAINTENANCE HANDBOOK GB ...

Page 2: ......

Page 82: ...P 80 Chap 12 Diagrams G B 12 Diagrams Hydraulic pneumatic plant diagram 12 1 ...

Page 85: ...P 83 Chap 12 Diagrams G B Power circuit wiring diagram 5 5 15 kW Machines with air dryer 12 3 ...

Page 86: ...P 84 Chap 12 Diagrams G B Power circuit wiring diagram 11 kW Machines with inverter 12 4 ...

Page 89: ...P 87 Chap 12 Diagrams G B Auxiliary circuit wiring diagram 11 kW Machines with inverter 12 7 ...