P. 70 - Chap. 10 Maintenance

G

B

-

Operation

Reference

To be carried

out by a

Service Centre

After the

first

100 hours

After the

first

1000 hours

Every

500

hours

Every

1000

hours

Every

2000

hours

Every

4000

hours

Overhaul minimum

pressure valve

•

Overhaul

intake valve

•

Replace

oil filter

10.6

•

•

•

Check - top up

oil level

10.5

•

• •

Change

oil

10.5

•

Replace

separator filter

10.6

•

Check

oil recovery system

•

•

Check

fitting tightness

•

•

•

Check

electrical terminal

connections

•

•

•

Drain

air-oil receiver

condensate

10.7

•

• •

Clean

radiators

•

•

Clean

dryer condenser

•

•

Replace

air dryer filters

•

•

Check

belt tension and wear

•

•

•

Replace

drive belts

•

Check

settings and

adjustments

•

Check

safety device

operation

•

*

This frequency relates to operation in normally

dust environments

. In the case of

critically dust

environments

, the control panel may signal the need to replace the air filter before the scheduled maintenance

time. In this case, replace the filter as soon as possible. The skilled personnel employed for installation will

be able to objectively evaluate the environmental conditions

Summary of Contents for FORMULA Series

Page 1: ...GENESIS FORMULA MODULO 5 5 15 kW USE AND MAINTENANCE HANDBOOK GB ...

Page 2: ......

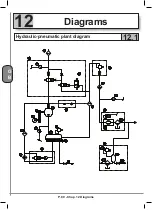

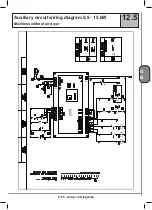

Page 82: ...P 80 Chap 12 Diagrams G B 12 Diagrams Hydraulic pneumatic plant diagram 12 1 ...

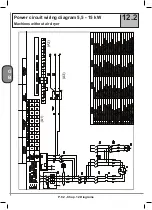

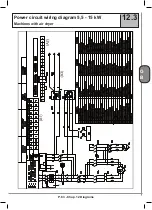

Page 85: ...P 83 Chap 12 Diagrams G B Power circuit wiring diagram 5 5 15 kW Machines with air dryer 12 3 ...

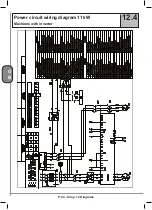

Page 86: ...P 84 Chap 12 Diagrams G B Power circuit wiring diagram 11 kW Machines with inverter 12 4 ...

Page 89: ...P 87 Chap 12 Diagrams G B Auxiliary circuit wiring diagram 11 kW Machines with inverter 12 7 ...