P. 72 - Chap. 10 Maintenance

G

B

Insert the filter fully on the intake valve

Fasten the clip.

Replace panels

PS

and

PF

of the

compressor cabinet

To reset the scheduled maintenance counter (for enabled users only), see paragraph 7.4.2.2.

GENESIS - FORMULA - MODULO 15 kW / 20 hp (BA 69)

GENESIS - FORMULA:

Open the corner panel

SPA

of the com-

pressor cabinet using the key provided

MODULO:

Open the filter panel

SF

of the compres-

sor cabinet using the key provided

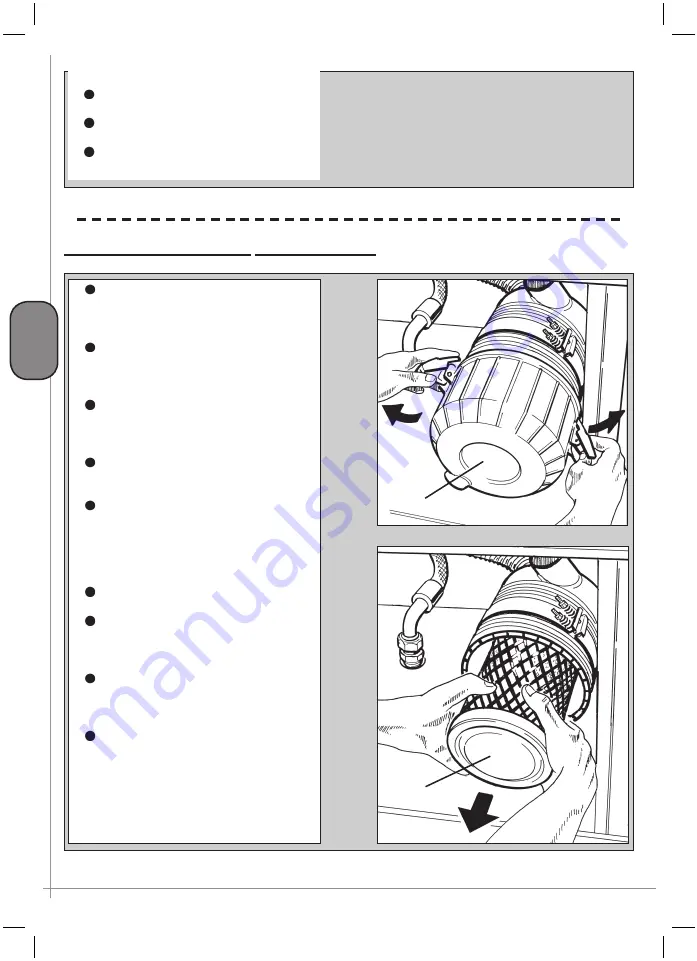

Release the front part of the filter con-

tainer

CF

pressing on the two fastening

tabs (

Fig. 39

)

Remove air filter

FA

from its housing as

shown in

Fig. 40

Clean the filter by directing a jet of air

inside it or replace the filter as pre-

scribed in the maintenance schedule.

Do not use fluids or detergents to clean

the filter

Replace filter

FA

inserting it fully

Re-attach the front part of the filter con-

tainer

CF

pressing on the two fastening

tabs

GENESIS - FORMULA:

Replace the corner panel

SPA

of the

compressor cabinet

MODULO:

Replace the filter panel

SF

of the com-

pressor cabinet

Fig. 39

Fig. 40

CF

FA

To reset the scheduled maintenance counter (for enabled users only), see paragraph 7.4.2.2.

Summary of Contents for GENESIS Series

Page 1: ...GENESIS FORMULA MODULO 5 5 15 kW USE AND MAINTENANCE HANDBOOK GB...

Page 2: ......

Page 82: ...P 80 Chap 12 Diagrams G B 12 Diagrams Hydraulic pneumatic plant diagram 12 1...

Page 85: ...P 83 Chap 12 Diagrams G B Power circuit wiring diagram 5 5 15 kW Machines with air dryer 12 3...

Page 86: ...P 84 Chap 12 Diagrams G B Power circuit wiring diagram 11 kW Machines with inverter 12 4...

Page 89: ...P 87 Chap 12 Diagrams G B Auxiliary circuit wiring diagram 11 kW Machines with inverter 12 7...