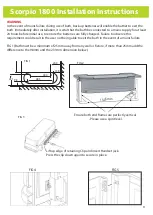

Base Plate Fixings

Floor Material

M8 Coach Screws

Joist & Noggin

M8 Coach Screws with nylon Plug

Brick & Block

*Sleeve Bolts

Compound

M8 Coach Screws with nylon Plug**

Flo

ati

ng

M8 Coach Screws with nylon Plug

Block & Beam

*M10 Sleeve Bolts

Concrete

Pre - Installation Requirements

Water Pressure Requirement

As the bath requires a Thermostatic Mixing Valve, which has been manufactured to NHS

engineering specification D08, and approved under the TMV scheme, please read the

following which outlines how a TMV may affect the use of your bath.

The working parameters of the TMV require a water pressure of 1-5 bar with a maximum

pressure loss ratio of no greater than 10:1 between hot and cold feeds. The maximum bath

water temperature according to D08 is no higher than 43°C and the maximum for the

shower is 39°C.

It is important to note that a pressure difference between hot and cold pipes will have a great

effect on the time it takes to fill a bath, i.e;

Hot water 1.4 bar and Cold water 2.4 bar = Approx. 9min. to fill with 180 litres

Hot water 2.2 bar and Cold water 2.2 bar = Approx. 5min. to fill with 180 litres

If in doubt a pressure test should be carried out prior to installation of the bath, and if required

a booster pump or pressure reducing valve fitted, as required.

POWER BATH FLOOR FIXING KIT (Supplied with Bath)

Contents Pack

M10 x 70mm Sleeve Bolts

6

M8 x 70mm Coach Screws

4

10 x 50mm Nylon Fixing Plugs 4

White Hole Cover Plugs

4

Note - It is a requirement that at least 4 firm fixings are made in the head end

base plate and 2 firm fixings in the foot end base plate. The table below shows

which type of fixing should be used based on the flooring.

*Sleeve bolts will not grip unless the hole is cleaned out first

**Plugs to be fixed into lower section of floor and not floating section

Should you experience difficulties please call our Technical Support Line 0870 066 0809

7