13

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

SOLUTION

No response when the

power is turned on

Power cord unplugged.

Defective power cord.

Tripped circuit breaker.

Tripped ground fault circuit interrupter.

Thermal overload on the motorized impeller

has tripped.

Plug power cord firmly into

electrical outlet in wall.

Check all connections and condition

of cords. Do not operate with

damaged power cord(s).

Reset breaker for building. Reset

12 amp breaker on control panel.

Reset GFCI on control panel and/or

at power source.

Turn unit "OFF", wait 30 minutes

and restart unit.

Circuit breaker on control

panel or building "trips".

Overloaded circuit.

Unplug any additional equipment

connected to the GFCI receptacle.

Reset circuit breaker. Restart unit

on "High" speed.

Filter change indicator is

"ON".

Loaded filters.

Excessive restrictions on intake.

Carbon filter has not been removed from

polybag.

Change in accordance with

operating instructions.

Reduce bends, length of flex duct,

or eliminate restrictions.

Remove carbon filter from polybag.

Note: If the unit does not start or malfunctions after carefully following the TROUBLESHOOTING GUIDE, call

Abatement Technologies service department at 800-634-9091 (U.S.) or 905-871-4720 (Canada) for assistance.

COMPONENT REPLACEMENT

Warning: To reduce the risk of fire, electrical shock or personal injury, always turn the unit “OFF” and

disconnect power cord from supply receptacle before removing the control panel, replacing the HEPA filter

and before cleaning or servicing the unit. This unit is equipped with an automatic restart motorized impeller

that will restart without warning after a temporary power interruption or recovery from a thermal overload

(over-heating) condition. Keep clear of the motorized impeller at all times to reduce the risk of injury.

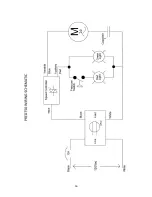

Occasionally a defective component will cause the unit to operate improperly or not at all. Any electrical

component can fail. Refer to the Wiring Diagrams and Wiring Schematics to diagnose the failure of any

component. Diagnostics should only be performed by a technician qualified to service electrical equipment.