2

PREDATOR® Portable Air Scrubber

Model: PRED750

Instruction Manual

© Abatement Technologies 2015 All Rights Reserved. No reproduction of any portion of this work is permitted

without the express written permission of Abatement Technologies, Inc.

READ AND SAVE THESE INSTRUCTIONS!

Note:

1.

Read and understand all operating instructions before using the Portable Air Scrubber.

2.

Save this manual for future reference.

This instruction manual provides important information on the use of the Predator

®

Portable Air Scrubber,

model PRED750. These instructions must be carefully followed in order to operate the unit safely and correctly.

If there are any questions regarding the use of the unit, please contact Abatement Technologies immediately at

800-634-9091 U.S. or 905-871-4720 Canada.

Abatement Technologies strongly urges users of air filtration units and related accessories to follow the most

recent guidelines and/or standards published by the Occupational Safety and Health Administration,

Environmental Protection Agency, and all other federal, state, provincial and local regulations.

GENERAL INFORMATION

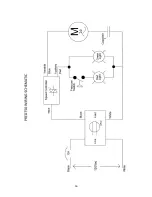

The PREDATOR® Portable Air Scrubber is a multi-use air filtration device, equipped with pre-filters and a HEPA

filter that are capable of filtering many airborne contaminants. An alternate carbon pre-filter for capturing low

concentrations of odors, vapors, gases, and volatile organic compounds, collectively known as OVG, is also

available.

Types of contaminants captured by particulate pre-filters, HEPA filter, or carbon filters:

•

Dirt

•

Lung-damaging particles

•

Low concentrations of OVG

•

Dust

•

Metal fumes

•

Low concentrations of Volatile

Organic Compounds (VOC)

•

Drywall dust

•

Smoke

•

Saw dust

•

Mold and fungal spores

•

Unpleasant nuisance odors

Note: To capture low concentrations of OVG, a Vapor-Lock

®

carbon filter must be used.

The PREDATOR® Portable Air Scrubber is capable of providing particulate and odor, vapor, gas filtration with

final stage filtration through a High Efficiency Particulate Air (HEPA) filter. This unit incorporates a series of

particulate filters that successively remove larger size to smaller size particles from the air. In addition to

providing HEPA filtration, the PREDATOR® Portable Air Scrubber is primarily used in a negative pressure or

recirculation mode. A negative pressure condition is created in order to confine contaminated airborne

particles. This condition exists when the static pressure inside the room containing the unit is lower relative to

the pressure of the environment outside the room. The static pressure differential is created and maintained by

continuously exhausting air out of a given room at a faster rate than air enters the room from all other sources.

In the recirculation mode, all of the filtered air is exhausted back into the room containing the unit.