7

BEFORE OPERATING THE UNIT, NOTE THE FOLLOWING:

Inspect and tighten any HEPA filter retaining nuts that may have loosened during transportation. Inspect the

filters for any material or structural damage prior to use and replace any damaged filters before operating the

unit. When removing any filters prior to operation, always put them back in place with airflow indicator on filter

housing oriented in the proper direction (if applicable).

Be sure to remove the foam plug from the inlet before use. Keep this foam plug so that the inlet can be plugged

again after use to contain any debris that has been captured in the machine.

As with any air filtration system, external airflow losses not attributable to the air filtration unit will reduce the

airflow of the system. The following recommendations can minimize airflow losses created by external static

resistance.

1.

Always use the minimum length of ducting possible with the fewest possible number of turns and

bends.

2.

Rigid metal ducting creates less turbulence and consequently less airflow loss than flexible ducting.

Regardless of the type of ducting used, rigid, “sweep-type’, radiused connections should be used for all

turns and bends.

3.

If flexible ducting is used, it must be kept as taut as possible to avoid flattening.

LOCATION OF THE UNITS AND MODES OF OPERATION

1.

Negative Pressure - used to help ensure that airborne contaminants do not escape from a contained

area, by maintaining negative (lower) air pressure within that area compared to adjacent areas. This is

generally accomplished by placing the unit inside the containment area and exhausting filtered air from

the unit out of the area. The filtered air must be exhausted outside of the containment area, either

directly to the outdoors, or into another part of the building. To maintain negative pressure, the air

exhaust must exceed the air supply by the greater of: 10% or 170 m

3

/h (100 CFM). To achieve this

differential, the air supply volume to the area may have to be reduced. Negative pressure levels should

be continuously monitored.

2.

Recirculation - used to reduce concentrations of airborne contaminants in a room or area by

continuously cleaning the air and exhausting it back into the same room or area.

3.

Positive Pressure - used to help prevent airborne contaminants from entering a containment area, by

keeping that area under positive pressure compared to adjacent spaces, so any air leakage will be an

outflow of clean air, and not inflow of contaminated air. This pressure differential can be established by:

a.

placing the unit inside the containment area, and using it to pull air into the area by attaching

flex duct between the inlet collar and a location outside of the containment area.

b.

placing the unit outside of containment area, and using it to push HEPA-filtered air into the area

through flex duct attached between the outlet collar and a location inside the area.

To ensure that the proper pressure differential is maintained, the volume of HEPA-filtered air supplied

to the area must be the greater of: 10% or 170 m

3

/h (100 CFM) higher than the volume of air exhausted

from it by the HVAC system. Positive pressure levels should be monitored continuously.

Important Note: Do not operate the unit unless the pre-filter(s) and HEPA filter are installed, and the filter

access door and panel are in place and closed.

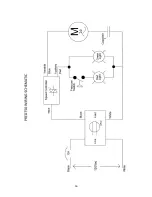

DAISY CHAINING

“Daisy Chaining” refers to the operation of multiple units on one circuit, with only one of the units plugged into

a 120V/15A electrical power supply receptacle. Each subsequent unit is plugged into one of the GFCI receptacles