Mounting

IM/265D/V-EN-02 265Dx,

265VS

25

Pos: 11.1 /Überschriften/1/M - O/Montage @ 0\mod_1140519732218_3101.doc @ 3159

4 Mounting

Pos: 11.2 /Überschriften/1.1/1-spaltig/A - C/Allgemeines @ 1\mod_1147677729750_3101.doc @ 10867

4.1

General

Pos: 11.3 /Montage/Druck/Druckmessumformer/Allgemein/Allgemeines @ 1\mod_1147677633390_3101.doc @ 10875

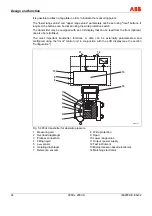

Before installing the transmitter, check whether the device design meets the requirements of the

measuring point from a measurement technology and safety point of view. This applies in

respect of the:

• Measuring

range

• Gauge

pressure

stability

• Temperature

• Explosion protection certification

• Operating

voltage

The suitability of the materials must be checked as regards their resistance to the media. This

applies in respect of the:

• Gasket

• Process connection, isolating diaphragm, etc.

In addition, the relevant directives, regulations, standards, and accident prevention regulations

must be observed (e.g., VDE/VDI 3512, DIN 19210, VBG, Elex V, etc.).

Measurement accuracy is largely dependent on correct installation of the pressure transmitter

and, if applicable, the associated measuring pipe(s). As far as possible, the measuring setup

should be free from critical ambient conditions such as large variations in temperature,

vibrations, or shocks.

Important

If unfavorable ambient conditions cannot be avoided for reasons relating to building structure,

measurement technology, or other issues, the measurement quality may be affected. (see the

section "Technical data").

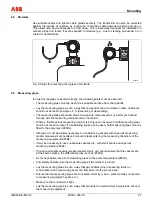

If a remote seal with capillary tube is installed on the transmitter, the additional operating

instructions for remote seals and the related data sheets must be observed.

Pos: 11.4 /======= Seitenumbruch ======== @ 0\mod_1126532365768_3101.doc @ 3830

Summary of Contents for 265DS

Page 87: ......