Maintenance / Repair

IM/265D/V-EN-02 265Dx,

265VS

79

Pos: 25.4 /Überschriften/1.1/1-spaltig/D - F/Demontage @ 5\mod_1162976675906_3101.doc @ 45386

12.1 Removal

Pos: 25.5 /Wartung / Reparatur/Druck/Druckmessumformer/Allgemein/Demontagehinweise @ 1\mod_1147936535984_3101.doc @ 12694

Warning - General risks

Before removing or disassembling the device, check for hazardous process conditions such

as pressure on the device, high temperatures, aggressive or toxic media, and so on.

Read the instructions in the sections "Safety" and "Electrical connection", and perform the

steps outlined there in reverse order.

Pos: 25.6 /Wartung / Reparatur/Druck/Druckmessumformer/Druckmessumformer 265Dx, 265Vx/Demontage / Montage der Prozessflansche @ 5\mod_1164106582078_3101.doc @ 49098

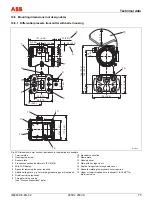

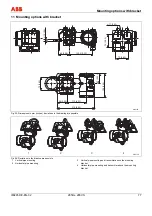

12.1.1 Removing / Installing the process flange

Caution - Risk of irreparable damage to measuring system

If remote seals are mounted on the measuring equipment, the process flange must not be

removed.

1.

Slacken the process flange screws by working on each in a crosswise manner (hexagon

head, SW 13 mm (0.51 inch)).

2.

Carefully remove the process flange, making sure that the isolating diaphragms are not

damaged in the process.

3.

Use a soft brush and suitable solvent to clean the isolating diaphragms and - if necessary -

the process flange.

Caution - Potential damage to parts

Do not use sharp or pointed tools.

4.

Insert the new process flange O-rings in the process flange.

5.

Attach the process flange to the measuring cell.

Caution - Potential damage to parts

Do not damage the isolating diaphragms.

The surfaces of both process flanges must be at the same level and at a right angle to the

electronics housing.

6.

Check that the process flange screw thread can move freely: Manually turn the nut until it

reaches the screw head. If this is not possible, use new screws and nuts.

7.

Lubricate the screw thread and seats of the screw connection using, for example, "Anti-Seize

AS 040 P" (supplier: P.W. Weidling & Sohn GmbH & Co. KG, Münster, Germany).

Important

In the case of oil and grease-free designs, clean the measuring chambers again if necessary

once the process flange has been installed.

8.

265Dx/265Vx transmitters with measuring ranges of

≥

60 mbar:

- First, use a torque wrench to tighten the process flange screws/nuts to a joining torque of

M

J

= 10 Nm (1.0 kpm), working in a crosswise manner.

- Then tighten them fully by turning each nut or screw again (in a crosswise manner) by the

tightening angle

α

A

= 180°, working in two stages of 90° each.

Summary of Contents for 265DS

Page 87: ......