22 OI/266/HART-EN Rev. D

| 2600T Series Pressure transmitters

266 Models - HART

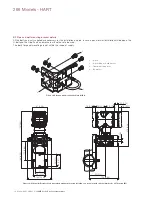

Transmitter housing rotation

To improve field access to the wiring or the visibility of the

optional LCD meter, the transmitter housing may be rotated

through 360° and fixed in any position. A stop prevents the

housing from being turned too far.

In order to proceed with housing rotation, the housing stop

tang-screw has to be unscrewed by approximately 1 rotation

(do not pull it out) and, once the desired position has been

reached, retightened.

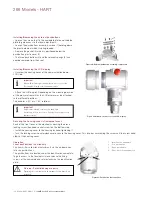

Integral Display Rotation

In case an optional integral display meter is installed, it is

possible to mount the display in four different positions rotated

clockwise or counterclockwise with 90° steps.

To rotate the LCD, simply open the windowed cover

(Hazardous area prescriptions must be respected), pull-out the

display housing from the communication board.. Reposition

the LCD connector according to the new desired position.

Push back the LCD module on the communication board. Be

sure that the 4 plastic fixing locks are properly in place.

Impulse piping connection for standard instruments

In order for the pipes to be laid correctly, the following points

must be observed:

– The measuring pipes must be as short as possible and free

from sharp bends.

– Lay the impulse piping in such a way that no deposits can

accumulate in them. Gradients should not be less than approx.

8 % (ascending or descending).

– The measuring pipes should be blown through with

compressed air or, better yet, flushed through with the

measuring medium before connection.

– Where a fluid/vaporous measuring medium is being used, the

liquid in both measuring pipes must be at the same level. If a

separating liquid is being used, both measuring pipes must be

filled to the same level (266Dx and 266Mx).

– Although it is not absolutely necessary to use balancing

vessels with vaporous measuring media, measures must be

taken to prevent steam entering the measuring chambers of

the measuring equipment (266Dx and 266Mx).

– It may be necessary to use condensate vessels, etc., with

small spans and vaporous measuring media (266Dx and 266Mx).

– If using condensate vessels (steam measurement), you

should ensure that the vessels are at the same elevation in the

differential pressure piping (266Dx and 266Mx).

– As far as possible, keep both impulse lines at the same

temperature (266Dx and 266Mx).

– Completely depressurize the impulse lines if the medium is a

fluid.

– Lay the impulse lines in such a way that gas bubbles (when

measuring fluids) or condensate (when measuring gases) can

flow back into the process line.

– Ensure that the impulse lines are connected correctly (High

and Low pressure sides connected to measuring equipment,

seals, etc.).

– Make sure the connection is tight.

– Lay the impulse line in such a way that prevents the medium

from being blown out over the measuring equipment.

Caution

Process leaks may cause harm or result in death.

Install and tighten process connectors and all accessories (including

manifolds) before applying pressure. In case of toxic or otherwise

dangerous process fluid, take any precautions as recommended in

the relevant Material Safety Data Sheet when draining or venting.

Use only a 12 mm (15/32 “) hexagonal spanner to tighten the

bracket bolts.

Figure 22: Housing rotation

Figure 23: LCD rotation

Summary of Contents for 266 HART Series

Page 40: ...40 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART Device Set up ...

Page 41: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 41 ...

Page 42: ...42 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART ...

Page 43: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 43 ...

Page 44: ...44 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART Display ...

Page 45: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 45 ...

Page 46: ...46 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART ...

Page 48: ...48 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART Calibrate ...

Page 49: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 49 Totalizer ...

Page 50: ...50 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART ...

Page 51: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 51 ...

Page 52: ...52 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART Diagnostics ...

Page 53: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 53 Device Info ...

Page 54: ...54 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART Communication ...

Page 77: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 77 ...

Page 78: ...78 OI 266 HART EN Rev D 2600T Series Pressure transmitters 266 Models HART ...

Page 79: ...2600T Series Pressure transmitters OI 266 HART EN Rev D 79 ...