- 15 -

ELECTRICAL REQUIREMENTS

The transmitter operates on a minimum voltage of 10.5 Vdc to

a maximum of 42

Vdc and is protected against polarity

inversion.

Note - The transmitter operates from 10.5 to 42

Vdc with no load (additional load allows operation

over 42V dc). For Ex ia and intrinsically safe approval

power supply must not exceed 30 Vdc.

In some countries the maximum power supply voltage

is limited to a lower value.

Installing optional devices the minimum voltage increases to:

- 10.5 Vdc with no option

- 10.7 Vdc with output analog indicator

- 12.5 Vdc with LCD ProMeter

- 12.3 Vdc with surge protection

- 13.3 Vdc with LCD CoMeter

- 15.3 Vdc with no link on output indicator plug

The total loop resistance is indicated in the expression below.

The Smart 2600T Transmitter Specification Sheets provide all

information concerning the Range and Span limits in relation to

the model and the sensor code.

The terminology currently used to define the various

parameters is as follows:

URL : Upper Range Limit of a specific sensor. The highest

value of the measured value that the transmitter can be

adjusted to measure.

LRL : Lower Range Limit of a specific sensor. The lowest value

of the measured value that the transmitter can be adjusted to

measure.

URV : Upper Range Value. The highest value of the measured

value to which the transmitter is calibrated.

LRV : Lower Range Value. The lowest value of the measured

value to which the transmitter is calibrated.

SPAN : The algebric difference between the Upper and Lower

Range Values. The minimum span is the minimum value that

can be used without degradation of the specified performance.

TURN DOWN RATIO : is the ratio between the maximum span

and the calibrated span.

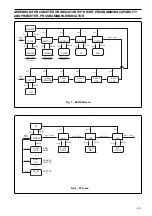

The transmitter can be calibrated with any range between the

LRL and the URL with the following limitations:

LRL

≤

LRV

≤

(URL - CAL SPAN)

CAL SPAN

≥

MIN SPAN

URV

≤

URL

RANGE AND SPAN CONSIDERATION

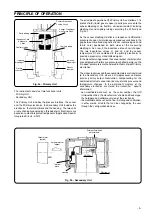

The total loop resistance is the sum of the resistance of all

elements of the loop, including wiring, conditioning

resistor,safety barriers and additional indicators (excluding the

equivalent resistance of the transmitter).

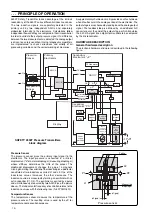

Where a configuration device (HART), such as the Hand Held

Communicator or a Modem is likely to be used, a resistance of

250 ohm minimum should be present between the power

supply and the point of insertion of these devices, to allow

communication.

Several types of safety barriers, either passive or active, can be

satisfactorily used in conjunction with the Smart 2600T

transmitters. Nevertheless, in case of use of active barriers,

check with the supplier if the model is suitable for use with

smart transmitters allowing the connection of the configuration

devices in the "safe" or non-hazardous area.

TRANSMITTER OUTPUT SIGNAL

The 2600T Safety transmitter provides both the analog 4

÷

20

mA and the digital HART communication. HART signals do not

affect safety during trading operations. HART writings are

permitted only in maintenance (out of safety) condition.

Analog Signal

Two-wire 4 to 20 mA dc, user-selectable for linear or square

root output; power of 3/2 or 5/2, 5th order or two 2nd order

switching point selectable programmable polynomial output

can be also selected for version with HART communication.

HART Signal

Digital process variable (%, mA or engineering units)

superimposed on the 4 to 20 mA signal, with protocol based on

Bell 202 FSK standard.

Output current limits (to NAMUR standard)

- Low saturation: 3.8 mA (field configurable from 3.5 to 4mA)

- High saturation: 20.5 mA (field configurable from 20 to 22.5 mA)

R (k

Ω

) =

Supply voltage - min. operating voltage (Vdc)

22.5

Transmitter failure mode (compliant to NE 43 NAMUR

regulation)

The output signal can be user-selected to a value of 3.7 or 22

mA on gross transmitter failure contition, detected by self-

diagnostics.

WARNING - The transmitter may be used as a

safety accessory (as defined by the Pressure Equipment

Directive 97/23/EC) i.e. as part of a shutdown system.

In this case it is recommended to select the correct fail

safe mode for the 4-20 mA signal (as per Namur NE43

recommendation).

See also the instructions relevant to fail safe selection

(Up/Down scale mode) in the addendum to the instruction

manual on "Use of hardware links on the secondary

electronics" .