- 3 -

Section

Page

INTRODUCTION .............................................................. 3

TRANSPORT, STORAGE, HANDLING AND

PRODUCT IDENTIFICATION .......................................... 4

SAFETY PHILOSOPHY, MANAGEMENT OF

FUNCTIONAL SAFETY AND INFORMATION

REQUIREMENTS ............................................................ 5

LIFE-CYCLE ACTIVITIES ................................................ 6

FAULTS OUTSIDE THE FUNCTIONAL SAFETY ........... 8

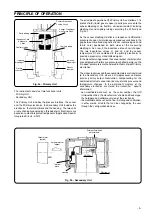

PRINCIPLE OF OPERATION .......................................... 9

INSTALLATION .............................................................. 12

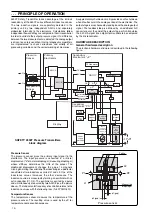

ELECTRICAL CONNECTIONS ..................................... 13

ELECTRICAL REQUIREMENTS .................................. 15

COMMISSIONING AND CONFIGURATION

ISSUES .......................................................................... 16

CALIBRATION ............................................................... 17

PRE-STARTUP ACCEPTANCE TEST,

PROOF TESTS AND

SAFETY RELATED PARAMETERS .............................. 19

DISMANTLING AND REASSEMBLY ............................ 20

SIMPLE FAULT FINDING .............................................. 22

RETURNING FORM ...................................................... 23

ADDENDUM FOR "METERS" OPTION OF

THE TRANSMITTERS ................................................... 24

ADDENDUM FOR COMETER OR INDICATOR

WITH HART PROGRAMMING CAPABILITY AND

PROMETER - PROGRAMMABLE INDICATOR ............ 25

ADDENDUM FOR PV-SCALING OPERATION ............. 30

ADDENDUM FOR "SURGE PROTECTOR" OPTION

OF THE TRANSMITTERS ............................................. 31

ADDENDUM USE OF HARDWARE LINKS

ON THE SECONDARY ELECTRONIC .......................... 34

ADDENDUM FOR DIFFERENTIAL PRESSURE

TRANSMITTERS : SELECTABLE OUTPUT

FUNCTIONS .................................................................. 35

ADDENDUM FOR FLANGE-MOUNTED

TRANSMITTERS ........................................................... 41

ADDENDUM FOR "EX SAFETY" ASPECTS

AND "IP" PROTECTION (EUROPE) ............................. 47

CONTENTS

INTRODUCTION

The 2600T series is a modular range of field mounted,

microprocessor based electronic transmitters, using a unique

inductive sensing element. Accurate and reliable

measurement of differential pressure, gauge and absolute

pressure, flow and liquid level is provided, in the even most

difficult and hazardous industrial environments.

Now a Safety pressure Transmitter is included in the 2600T

Series, with its analog output signal plus HART digital

communication.

The HART digital protocol allows remote re-ranging,

calibration and diagnostics, without any interference with the

standard 4-20 mA analog output signal.

This operating instructions manual describes the Safety

version of the 2600T Series transmitters and specify all

information necessary to safely connect the Safety 2600T

pressure transmitter in a Safety Instrumented System.

It details also how the signals from the input field device should

be interpreted.

Refer to the shortened contents of this manual, here in this

page for addressing the section of your interest, and also to the

supplementary documentation for additional remarks.

Reference information on remote seals and configuration of

the transmitter can be found in the following documents:

SS/S26

Remote Seal Specification

SS/268xx

Data Sheets

IM / 691HT

Hand-Held Communicator

Online HELP SMART VISION Configuration Program

IEC 61508 Functional Safety of e/e/pe Safety-related systems

ISA S84.01 Application of Safety Instrumented Systems for

the Process Industries

NE43 Standardization of the signal level for the breakdown

information of digital transmitters

Other help ful or general information can be found in the ABB

web site, at www.abb.com

SUPPLEMENTARY DOCUMENTATION