Summary of Contents for 3AXD50000018602

Page 1: ... ABB DRIVES ACS880 01 C135 drives with flange mounting kit Supplement ...

Page 2: ... ...

Page 4: ......

Page 24: ...24 Mechanical installation 4 Attach the top and bottom U brackets to the drive 4 M5 nut 6 N m ...

Page 46: ...46 Dimension drawings Frame R1 3AXD50000024531 ...

Page 47: ...Dimension drawings 47 Attaching points and opening dimensions 3AXD50000024858 ...

Page 48: ...48 Dimension drawings Frame R2 3AXD50000024532 ...

Page 49: ...Dimension drawings 49 Attaching points and opening dimensions 3AXD50000024859 ...

Page 50: ...50 Dimension drawings Frame R3 3AXD50000024533 ...

Page 51: ...Dimension drawings 51 Attaching points and opening dimensions 3AXD50000024860 ...

Page 52: ...52 Dimension drawings Frame R4 3AXD50000030170 ...

Page 53: ...Dimension drawings 53 3AXD50000030170 Hood is needed for UL Type 12 installation only ...

Page 54: ...54 Dimension drawings Attaching points and opening dimensions 3AXD50000027190 ...

Page 55: ...Dimension drawings 55 Frame R5 3AXD50000027088 ...

Page 56: ...56 Dimension drawings 3AXD50000027088 Hood is needed for UL Type 12 installation only ...

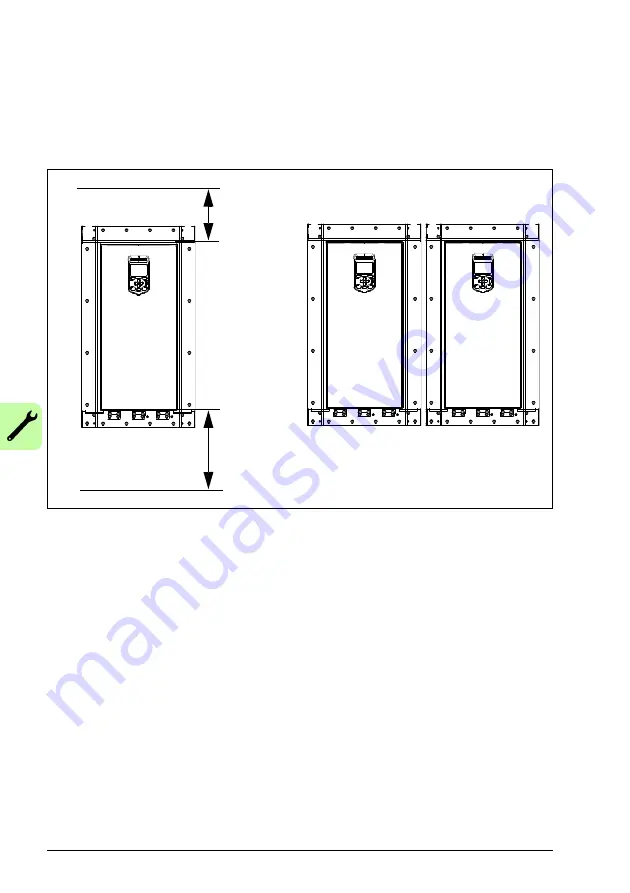

Page 57: ...Dimension drawings 57 Attaching points and opening dimensions 3AXD50000018602 ...

Page 58: ...58 Dimension drawings Frame R6 3AXD50000021919 ...

Page 59: ...Dimension drawings 59 Hood is needed for UL Type 12 installation only 3AXD50000021919 ...

Page 60: ...60 Dimension drawings Attaching points and opening dimensions 3AXD50000019323 ...

Page 61: ...Dimension drawings 61 Frame R7 3AXD50000021920 ...

Page 62: ...62 Dimension drawings Hood is needed for UL Type 12 installation only 3AXD50000021920 ...

Page 63: ...Dimension drawings 63 Attaching points and opening dimensions 3AXD50000019324 ...

Page 64: ...64 Dimension drawings Frame R8 3AXD50000021921 ...

Page 65: ...Dimension drawings 65 Hood is needed for UL Type 12 installation only 3AXD50000021921 ...

Page 66: ...66 Dimension drawings Attaching points and opening dimensions 3AXD50000019325 ...

Page 67: ...Dimension drawings 67 Frame R9 3AXD50000021922 ...

Page 68: ...68 Dimension drawings 3AXD50000021922 Hood is needed for UL Type 12 installation only ...

Page 69: ...Dimension drawings 69 Attaching points and opening dimensions 3AXD50000019326 ...

Page 70: ...70 Dimension drawings ...

Page 72: ...72 Mounting examples Frame R1 ...

Page 73: ...Mounting examples 73 ...

Page 74: ...74 Mounting examples V PP 6 7 21 6 ...

Page 75: ...Mounting examples 75 Frame R2 ...

Page 76: ...76 Mounting examples ...

Page 77: ...Mounting examples 77 6 7 21 6 V PP ...

Page 78: ...78 Mounting examples Frame R3 ...

Page 79: ...Mounting examples 79 ...

Page 80: ...80 Mounting examples 6 7 21 6 V PP ...

Page 81: ...Mounting examples 81 Frame R4 ...

Page 82: ...82 Mounting examples ...

Page 83: ...Mounting examples 83 6 7 21 6 V PP ...

Page 84: ...84 Mounting examples Frame R5 ...

Page 85: ...Mounting examples 85 ...

Page 86: ...86 Mounting examples 6 7 21 6 V PP ...

Page 87: ...Mounting examples 87 Frame R6 ...

Page 88: ...88 Mounting examples ...

Page 89: ...Mounting examples 89 6 7 21 6 V PP ...

Page 90: ...90 Mounting examples Frame R7 ...

Page 91: ...Mounting examples 91 ...

Page 92: ...92 Mounting examples 6 7 21 6 V PP ...

Page 93: ...Mounting examples 93 Frame R8 ...

Page 94: ...94 Mounting examples ...

Page 95: ...Mounting examples 95 6 7 21 6 V PP ...

Page 96: ...96 Mounting examples Frame R9 ...

Page 97: ...Mounting examples 97 ...