12

230

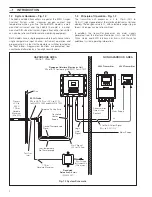

Remove cover (see Fig. 4.1)

Slacken captive screws

and remove

protection cover

Remove front

panel screws

Remove front

panel

Remove cap

and screw

230

230V

115V

1

2

3

4

3

Select the mains

voltage required

5

Select

the mains

voltage

required

115

115

115V

230V

115

4

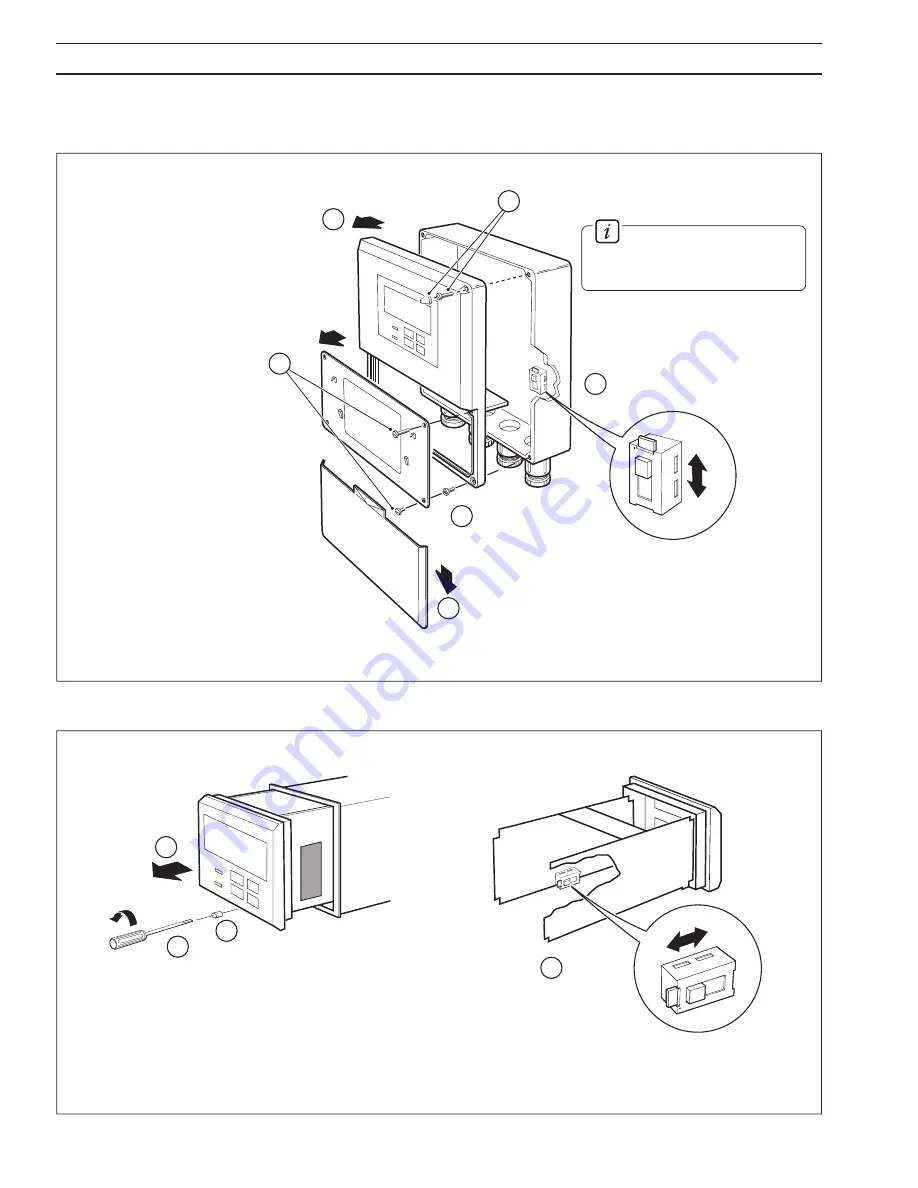

Slide instrument

out of case

Undo captive

screw

Remove plug

(if fitted)

1

2

3

…4

ELECTRICAL CONNECTIONS

4.4

Selecting the Mains Voltage

4.4.1

Wall/Pipe-mounted Instruments – Fig. 4.6

4.4.2

Panel-mounted Instruments – Fig. 4.7

Information.

Use a small,

flat-bladed screwdriver to remove

the screw cap from the case.

Fig. 4.6 Selecting the Mains Voltage – Wall/Pipe-mounted Instruments

Fig. 4.7 Selecting the Mains Voltage – Panel-mounted Instruments