- 4 -

OPERATIVE LIMITS

The transmitter operates on a minimum voltage of 10.5 Vdc to

a maximum of 55

Vdc and is protected against polarity

inversion.

Note - The transmitter operates from 10.5 to 42

Vdc with no load (a load up to 620

Ω

allows operation

up to 55 Vdc). For EEx ia and intrinsically safe (FM,

CSA and SAA) approval power supply must not

exceed 30 Vdc.In some countries the maximum

power supply voltage is limited to a lower value.

Installing optional devices the minimum voltage increases to:

- 10.5 Vdc with no option or with integral digital display

- 10.7 Vdc with output analog indicator

- 12.5 Vdc with output LCD indicator

- 12.1 Vdc with surge protection

- 14.1 Vdc with LCD indicator and surge protection

- 13.1 Vdc with LCD CoMeter

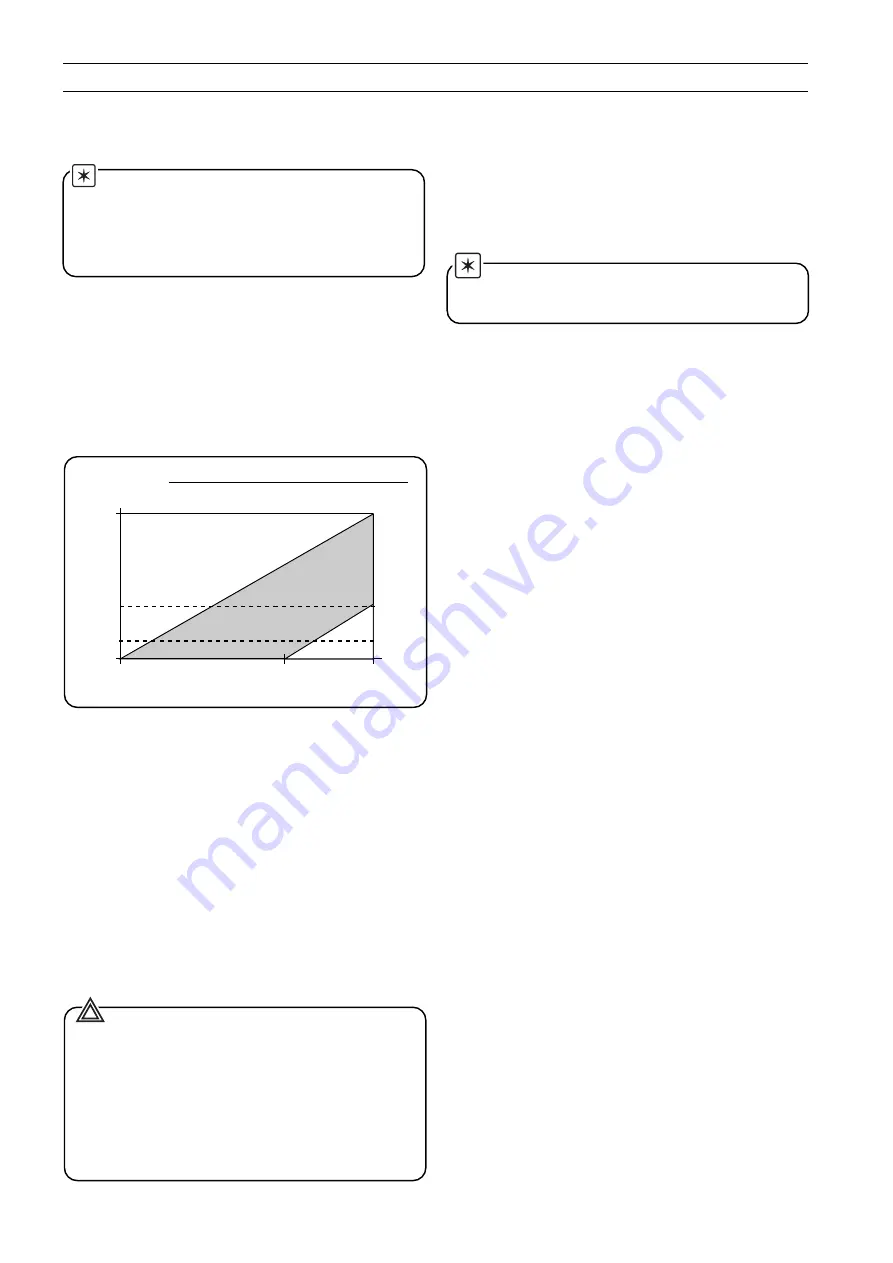

The total loop resistance is indicated in the figure and

expression below.

The total loop resistance is the sum of the resistance of all

elements of the loop, including wiring, conditioning resistor,

safety barriers and additional indicators (excluding the

equivalent resistance of the transmitter).

Where a configuration device (HART), such as the Hand Held

Communicator or a Modem is likely to be used, a resistance of

250 ohm minimum should be present between the power

supply and the point of insertion of these devices, to allow

communication.

Several types of safety barriers, either passive or active, can be

satisfactorily used in conjunction with the Smart 600T EN

transmitter. Nevertheless, in case of use of active barriers,

check with the supplier if the model is suitable for use with

smart transmitters allowing the connection of the configuration

devices in the "safe" or non-hazardous area.

WARNING - The transmitter may be used as a

safety accessory (as defined by the Pressure Equipment

Directive 97/23/EC) i.e. as part of a shutdown system.

In this case it is recommended to select the correct fail safe

mode for the 4-20 mA signal (as per Namur NE43

recommendation).

See also the instructions relevant to fail safe selection (Up/

Down scale mode) in the addendum to the instruction

manual on "Use of hardware links on the secondary

electronics" .

R (k

Ω

) =

Supply voltage - min. operating voltage (Vdc)

22

Supply voltage

Total loop resistance 250

(ohms)

2020

25 (ref.)

10.5

55 (volts)

42

4 to 20 mA and

HART digital communication

620

4 to 20 mA only

600

Temperature limits

°

C (

°

F) :

• Ambient (is the operating temperature)

All models and sensors can withstand without damages or

leakages temperatures from -40 to +85

°

C, -40 to +185

°

F.

-20

°

C, -4

°

F for Viton gaskets.

See the instrument data sheets for temperature effect on

response time and accuracy.

Note: For Hazardous Atmosphere application see the

temperature range specified on the certificate/approval

relevant to the aimed type of protection.

• Process (1)

Lower limit

- refer to lower ambient limits

- -20

°

C (-4

°

F) for Viton gaskets

Upper limit

- Silicone oil and KTFILL-1 filling : 120

°

C (248

°

F) (2)

- Inert fluid filling : 100

°

C (212

°

F) (3)

(1) Process temperature above 85

°

C (185

°

F) requires derating the

ambient limits by 1.5 : 1 ratio.

(2) 100

°

C (212

°

F) for application below atmospheric pressure

(3) 65

°

C (150

°

F) for application below atmospheric pressure

Pressure Limits

For model number see the first five characters of Product

Code on label Ref. A.

The sensor code is the sixth character.

• Lower : 0.067 kPa abs, 0,67 mbar abs, 0.01 psia

(0.13 kPa abs, 1.33 mbar abs, 0.02 psia for sensor code A).

Double the lower limit with inert filling

• Upper

- model 6X1ED, EG, EA

sensor codes B to W : 14 MPa, 140 bar, 2030 psi

sensor code A : 8 MPa, 80 bar, 1160 psi

sensor code U : 25 MPa, 250 bar, 3620 psi

- model 6X1EE :

all sensor codes : 25 MPa, 250 bar, 3620 psi

- model 6X1EH :

all sensor codes :1 MPa, 10 bar, 145 psi

- model 622ED :

sensor codes R, E, F : 42 MPa, 420 bar, 6090 psi

sensor code L : 32 MPa, 320 bar, 4640 psi

- model 6X1ES

10 MPa, 100 bar, 1450 psi or the following flange/fitting

rating of the seal, whichever is less.

• flanged seals (S6E/S6F)

ANSI CL 150 : 2 MPa, 20 bar, 290 psi

ANSI CL 300 : 5 MPa, 50 bar, 725 psi

ANSI CL 600 : 10 MPa, 100 bar, 1450 psi

ANSI CL 900 : 16 MPa, 160 bar, 2320 psi

DIN ND 16 : 1.6 MPa, 16 bar, 230 psi

DIN ND 40 : 4 MPa, 40 bar, 580 psi

DIN ND 64 : 6.4 MPa, 64 bar, 930 psi

DIN ND 100 : 10 MPa, 100 bar, 1450 psi

DIN ND 160 : 16 MPa, 160 bar, 2320 psi

• sanitary seals (S6S)

2in Triclamp : 3.8 MPa, 38 bar, 550 psi

3in Triclamp : 2.4 MPa, 24 bar, 350 psi

4in Triclamp : 1.7 MPa, 17 bar, 250 psi

F50/F80 Union nut : 2.5 MPa, 25 bar, 360 psi

Summary of Contents for 6X1ED

Page 6: ... 6 CORROSION TABLE ...

Page 7: ... 7 CORROSION TABLE ...

Page 8: ... 8 CORROSION TABLE ...

Page 9: ... 9 CORROSION TABLE ...

Page 14: ... 14 ...

Page 16: ... 16 PED600TEN Rev 1 ...