11

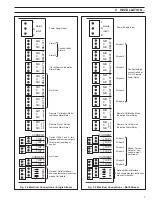

Reagent

(Violet)

Peristaltic Pump

De-gassing

Block

Zero

Solution

(Green)

Secondary

Standard

(Yellow)

Pre-heating Coil

Delay Coil

Heated

Reaction

Block

Overflow

Drain

SV1

SV2

Cuvette

Cuvette

Vent/

Drain

Drain Valve

Drain

Air

Bubble

Path

Reacted

Sample

Sample

Reagent

Mixer

Block

Optical

System

Heater

Reaction

Block

Heater

Blue

Blue

Blue

Vi

olet

Sample

from

Constant

Head

Unit(s)

SV4

SV5

Green

Orange

Drain

Color

Comp.

Manifold

Sample path during color compensation.

Blue

Green

4

LIQUID HANDLING SECTION…

4.2

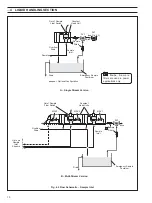

General Operation – Figs. 4.2 and 4.3

The sample enters the constant head unit situated at the

bottom of the instrument case – see Fig. 4.2A for single stream

and Fig. 4.2B for multi-stream. The constant head units are

fitted with an 'Out of Sample' switch. This switch is used by the

microprocessor, in the appropriate situation, to instigate the

'Out of Service' alarm and energize the emergency sample

valve, if fitted. This optional valve introduces sample from an

alternative supply to maintain the monitor operation when the

sample has been lost. This avoids potential problems caused

when the monitor is run without a sample for long periods.

For the multi-stream version, each sample is presented to

individual constant head units each of which is fitted with an

'Out of Sample' switch (see Fig. 4.2B). Solenoid valves, MSV 1

to 6, attached to each constant head unit are then used to

select each stream to be sampled. The emergency sample

valve is energized when all sample streams are lost or de-

selected.

The sample is drawn off from the selected stream by one

channel of the peristaltic pump via the pre-heating coil – see

Fig. 4.2B. The purpose of this coil is to pre-heat the sample

prior to the reaction taking place. Any air bubbles which form in

the sample are removed by the de-gassing block and pumped

to the drain by one channel of the peristaltic pump via valve

SV5 (in the multi-stream version the sample is passed directly

to drain). This is important because bubbles in the sample will

give variable reagent mixing resulting in noisy readings on the

display.

The reagent solution, delivered via one channel of the pump is

then added to the sample before entering the dynamic mixer

block and then passes through the heated delay coil where the

reaction takes place. The resultant solution is then presented

to the measuring cuvette via a solenoid valve SV4 (in the multi-

stream version the solution is passed directly to the cuvette).

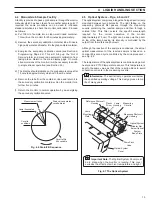

Information. The dynamic mixer consists of a

small stirrer situated in a chamber in the mixer block and is

magnetically coupled to a small electric motor.

During an AUTO ZERO, solenoid valve SV1 is used to

introduce the primary standard solution. Solenoid valve SV2 is

used to introduce the secondary standard solution.

The sample pre-heater coil and reaction delay coil are

mounted in a single acrylic block. This block is heated using a

small 24 V cartridge heater and controlled using a PT100

temperature sensor. This optimizes the chemical reaction time

and removes the effect of ambient and sample temperature

changes.

The coils are made from PTFE and do not normally require any

maintenance except for the 5-weekly system flush – see

Section 8.2.2.

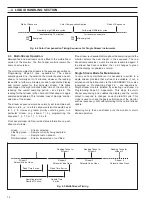

If the color compensation sequence is initiated, both SV4 and

SV5 valves are energized. The developed solution passes to

drain and is replaced by undeveloped solution (sample without

reagent) which passes to the cuvette via valve SV5.

After a preset number of fill/drain cycles a measurement of

absorbance is made. This is converted to a phosphate reading

which is then subtracted from the reading on developed

solution. The value displayed is then the color compensated

phosphate concentration.

Timing for the color compensation sequence is shown in

Fig. 4.4.

Fig. 4.3 Flow Schematic of Chemical Section

Note. The color

compensation manifold

and valves SV4 and SV5

are not fitted in the multi-

stream version.