____________________________________________________________________________________________________________

G1

Introduction to AC500

1-71

AC500 / Issued: 07.2006

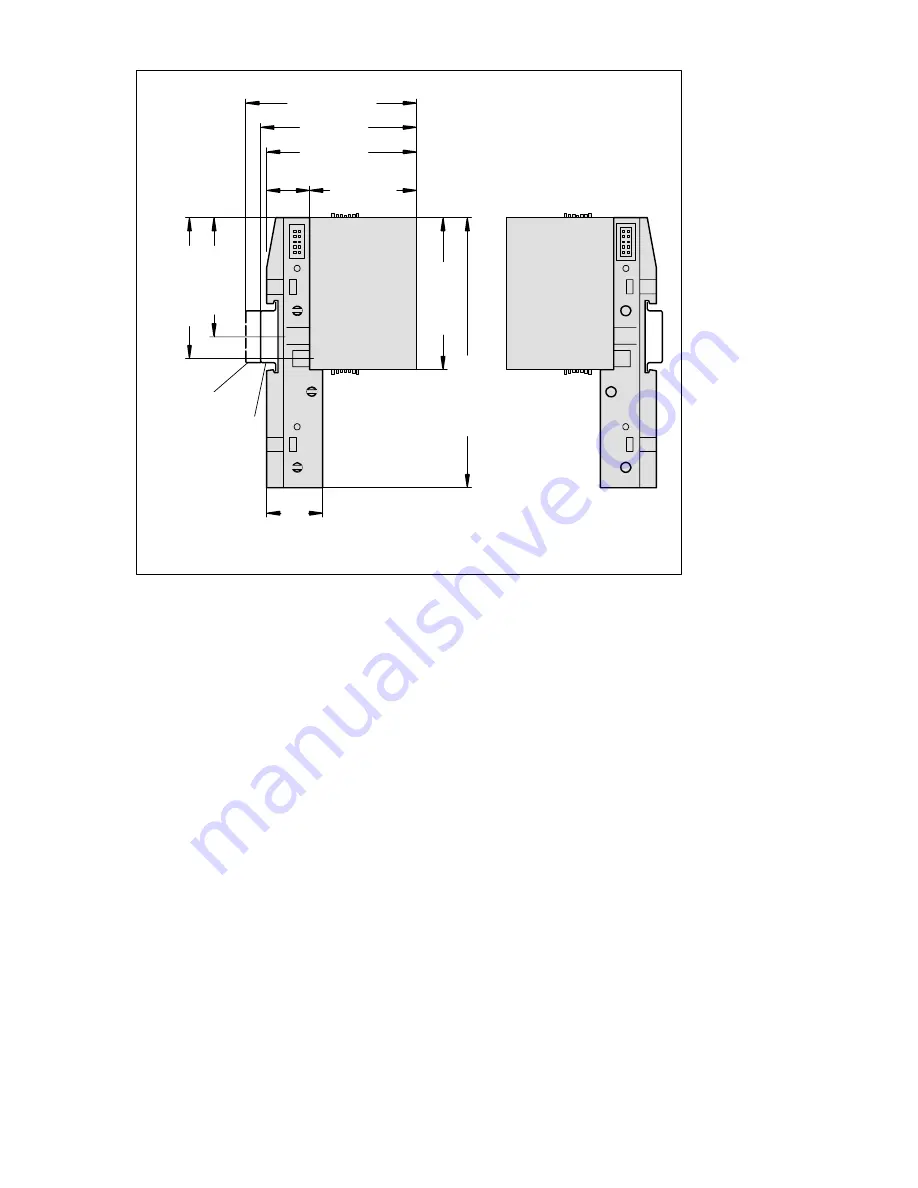

28

21 (0.83)

54 (2.13)

75 (2.95)

59 (

2

.32)

70.5 (

2

.78)

135 (

5

.31)

76 (

2

.99)

View on the left side

View on the right side

77 (3.03)

84.5 (3.33)

DIN rail 15 mm

DIN rail 7.5 mm

135 mm

(5.31) inches

Dimensions:

(1.10)

Figure: Dimensions of the Terminal Unit with module (lateral view)

Note:

All dimensions are in mm (in.). Hole spacing tolerance: ±0.4 mm (0.016 in.)