There are three important principles to be especially considered:

–

Keep all connections as short as possible (in particular the grounding con-

ductors)

–

Use large conductor cross sections (in particular for the grounding conduc-

tors)

–

Create low-impedance, i.e. good and large-sized contacts (in particular for

the grounding conductors)

Pay attention to the following:

–

Use vibration-resistant connections

–

Clean metallic contact areas

–

Use solid plug and screw-type connections

–

Use earth cable shields with clips on a well-grounded metallic surface

–

Do not use aluminium parts

–

Do not use sheath wires

–

Do not use toothed lock washers under screw connections

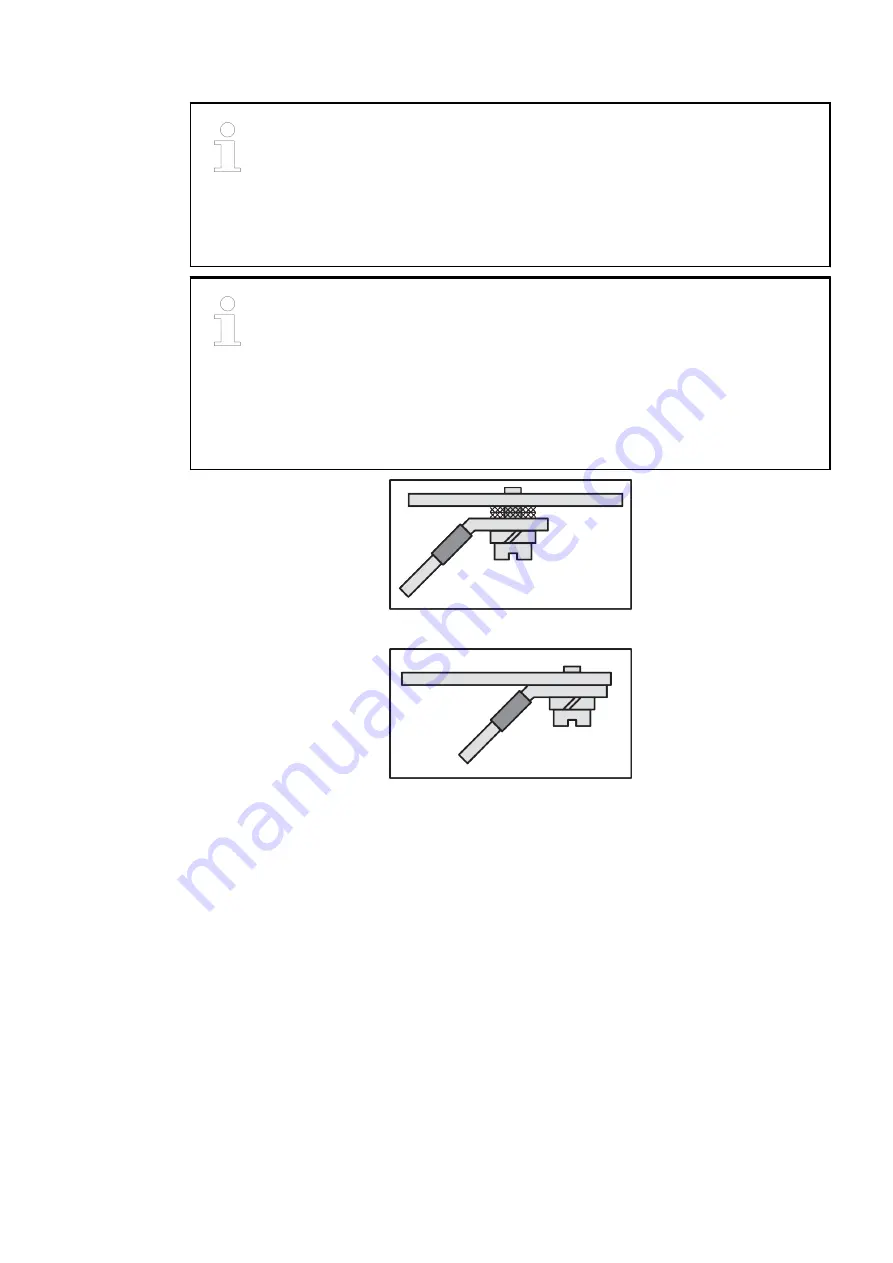

Fig. 173: Assembly: wrong

Fig. 174: Assembly: correct

Make a connection between the DIN rails and PE (Protective Earth). For this, use an grounding

wire with a minimum conductor cross section of 10 mm

²

.

The wire is connected to the DIN rail with an M6 screw.

A large-area contact of the DIN rail with the metallic mounting plate improves the EMC behavior

significantly, as the disturbances can be discharged more effective.

2.4.4.2

Cable routing

● Route cables meeting the standards.

● Sort the cables into cable groups:

–

Power current cables

–

Power supply cables

–

Signal cables

–

Data cables

System assembly, construction and connection

Overall information (valid for complete AC500 product family) > EMC-conforming assembly and construction

2022/01/31

3ADR010278, 3, en_US

919